|

|

1906

|

|

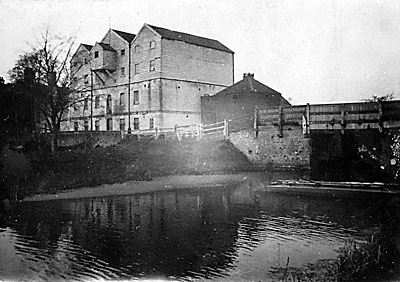

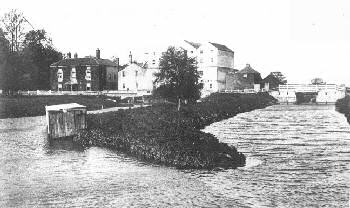

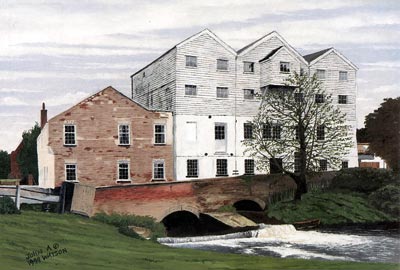

Buxton Mill

River Bure |

|

|

1906

|

|

Buxton watermilll was recorded in Domesday in 1085. It was last rebuilt as a mill in 1754 by William Pepper, a merchant living in Buxton. The building was constructed of white painted brick and weatherboard with a pantile roof and has been a prominent landmark in the village for many years. It finally ceased as a working mill one sad Saturday in August 1970 when Duffields finally closed the complex in order to concentrate their business at the larger site at Saxlingham Thorpe. |

|

|

c.1906 with one wherry in the lock and one moored |

|

|

Mill

dam c.1910 - the lock is to the left

|

|

|

Buxton lock in 1928 |

Buxton lock exit in 1928 |

|

William Pepper's mill was a clever design, using two wheels, the larger being breastshot. The smaller wheel was overshot using water that formed part of the Aylsham Navigation and gained its head by the lock system at Buxton. The only other mills to use overshot wheels in Norfolk that I have found so far were at Brandiston, Congham, Foulden, Hingham, Mundesley, Tharston and Weybourne. The building was constructed of white painted brick and weatherboard with a pantile roof. |

|

|

Probable original river course on right 12th October 2008 |

|

The Bure has

become quite large and powerful by the time it reaches Buxton and with

a fall of 6 to 7 feet thanks to the river being diverted, a considerable amount of power is available. The

conventional breastshot waterwheel was changed to a Victor turbine in

the 1902 in order to improve efficiency. The turbine, being quite small,

revolved at a much faster pace. This avoided the need to introduce several

gear wheels, which on larger, slow moving wheels waste considerable power

in overcoming friction. In 1965 this turbine was still producing 25% of

the mill's power requirements. It had undergone a minor overhaul in 1930

and a major overhaul in the 1960s that would have left it capable of running

for the next 40 years. |

|

|

October 1963 |

|

|

|

Mill

dam September 1967

|

March 1967 - the lock was near the white gate |

|

Assignment from Sir Thomas Frankland knight to Stephen Ashby (Thomas,

Lord Londonderry also a party) of mortgage originally raised in 1698 by

William, Earl of Yarmouth, and Charles, Lord Paston, by Common Recovery,

on the manors of Sparham, Buxton and Skeyton, Buxton Park, watermills

in Buxton and Lammas called Buxton Mills, and lands etc. in Buxton, Hevingham,

Lammas, Stratton Strawless, Brampton, Sparham, Bawdeswell and Great_Witchingham. |

November 4th |

As an Opinion has lately prevailed that the MILLERS have always refused to grind Corn for the Poor or other Persons in small Quantities or if they did, that Abuses were made use of to damage the same; To remove such Prejudices for the future, we whose Names are hereunder subscribed, residing in the several Parishes mentioned with our Names, have engaged for the Time to come or until the Prices of Corn shall be very considerably reduced, to grind (at Threepence per Bushel) Corn in small Quantities for the Poor and other Persons in the speediest, best and most proper Manner and deliver the same without and Adulteration. |

John Withers, Northwalsham Robert Colls, Worstead Wm. Pepper & Co. Buxton Robert Parmeter, Aylsham |

N.B. MEAL will be sold by us in small Quantities as cheap as the Prices of Corn, which we shall be oblig'd to give, will possibly admit of. Norwich Mercury - 15th November 1766 |

| N.B. The average price of wheat in 1766 was £2. 3s. 1d. per quarter. |

Water Mills. |

The Remainder of the Lease of Buxton Water-Mills, in the County of

Norfolk, in the Centre of a fine and plentiful Corn Country, within eight

Miles of the City of Norwich, situated upon the River Bure, navigable

from Aylsham (by the said Mills) to Coltishall and Yarmouth. |

Benjamin Richmond, b.1796 at Scratby and son of Edward and Mary Richmond, was employed at the mill c.1820 - c.1825. He married Elizabeth Braddock on 9th June 1818 at Buxton and they had two children William in 1820 and Mary Ann in 1825, before moving to Yarmouth where they had 4 more children. |

|

BUXTON MILLS. |

| Capital and well-built WATER CORN MILL, at Buxton, in

Norfolk, capable of manufacturing at least forty lasts a week, with a convenient

modern-built Messuage attached to the Mill: also two Cottages, Stables,

Chaise-house, Granaries, Drying Kiln, and other requisite Out-buildings,

in excellent repair, and twelve Acres of Land adjoining the Premises, divided

into Gardens, Pleasure Grounds, and Meadows. The Mill is situate on the

river Bure, which is navigable to Yarmouth, and is a very fine stream of

water. These Premises are 8 miles distant from Norwich, 6 from North Walsham, and 4 from Aylsham, (three of the best corn markets in the county,) and are situate in a very fine corn country. For further particulars apply Messrs Sewell and Blake, solicitors, Norwich. Norwich Mercury - 8th December 1821 |

To Millers |

|

|

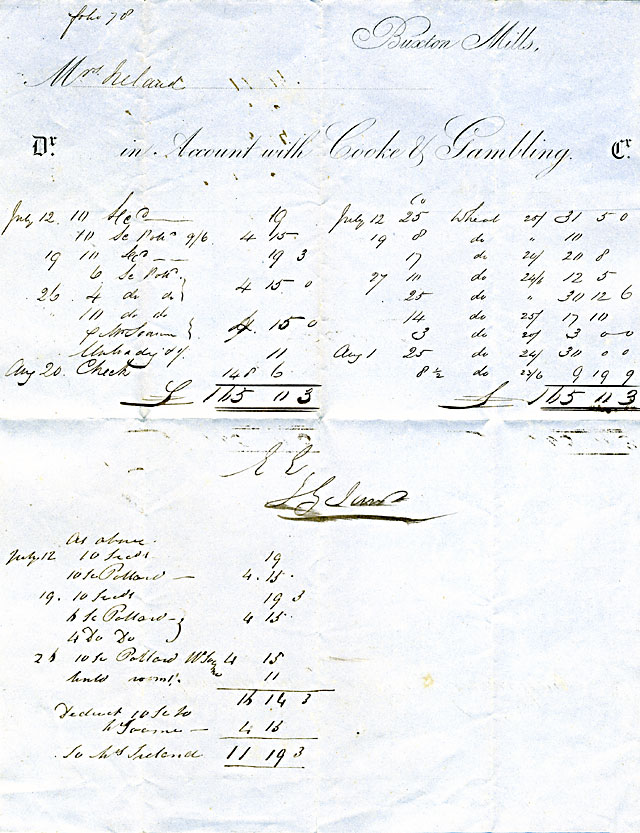

Cooke & Gambling invoice to Mrs. Heland - 1833 |

|

In

August 1860 a new axle was required for one of the waterwheels:

|

|

St. Ann's Iron Works, King Street, Norwich, Aug. 18/60. Mr. Howlett, Dear Sir, Agreeable to your request I beg to hand you price for one New Cast Iron Water Wheel Shaft, with 2 Gun Metal Neck Bearings, 2 bridgin Pots, fitted with Wrought Iron Wedges and Screws. to be same size and length as present one at the Buxton end of the Mill. The above to be Turned and fitted ready for fixing in the Mill for the sum of forty-nine pounds, ten shillings. £49.10. -. The whole to be done in a Workman-like Manner. Waiting your reply I am, Dear Sir, Your Obt. Servt, Thos. Smithdale. |

The Frankling and Pratt families were related by marriage and both were connected with the milling trade. |

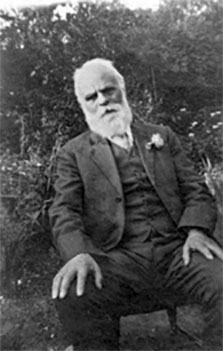

Thomas Shreeve (1833 -1909) came from Bolwick_watermill and Marsham_postmill and had moved to Buxton. by 1890. Thomas' nephew Charles Robert Shreeve (1854-1932) took over at Bolwick_mill and Marsham_postmill and was possibly still there when his farming business became insolvent in 1897. Thomas' nephew George Holland Shreeve moved from Dilham Mill to join Thomas at Buxton by 1891. |

|

George Holland Shreeve - c.1920 |

|

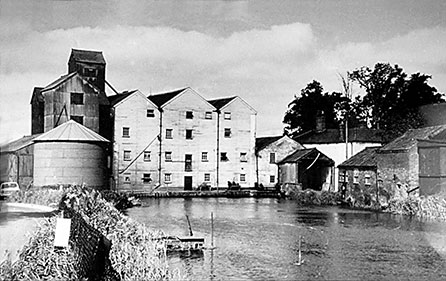

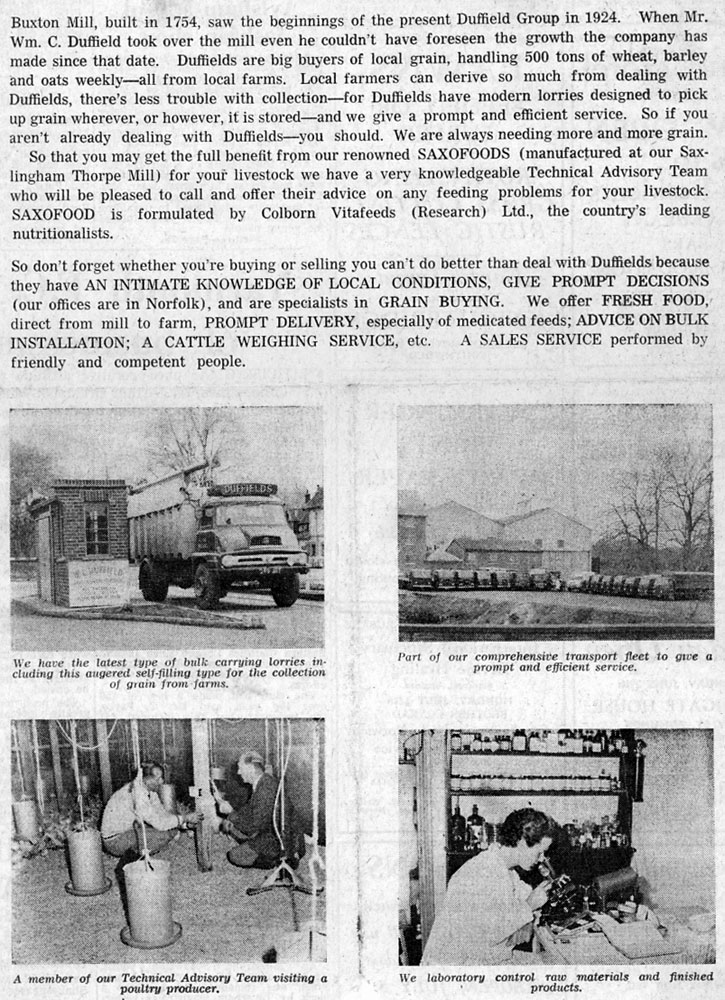

Many extensions

were made to the mill and its outbuildings were often added to when extensive

silos and storage facilities were added to help cope with the higher throughput

of the modern mill. The first of these was a 125 ton silo that was added

in 1930, followed by a dryer in 1947. |

|

98% of wheat milled was locally grown and Duffields were handling 500 tons of local grain (wheat, barley and oats) between their 3 mills - Buxton, Tharston and Saxlingham Thorpe. |

|

|

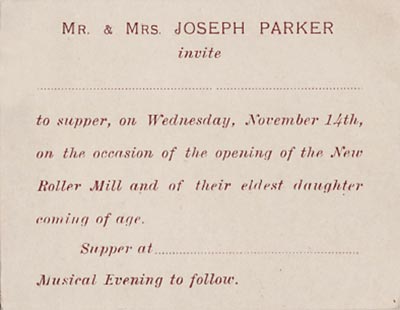

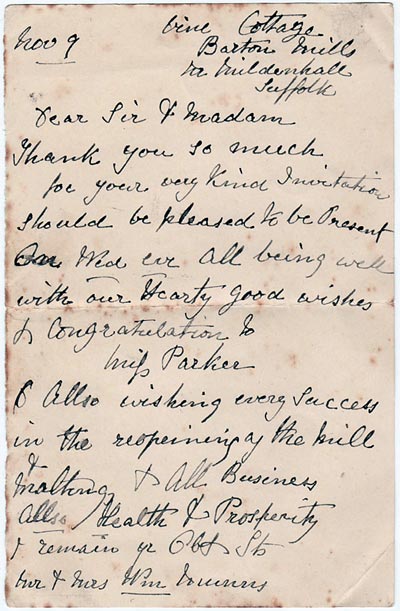

Roller mill invitation November 1906 |

Roller mill reply November 1906 |

|

|

The lock beside the mill c.1910 |

The old canal cut 12th October 2008 |

|

The great floods of 1912 wreaked havoc in Buxton and the surrounding countryside. The flood came at the end of a dismal August. The rain began at 3.00am on Monday 26th August and continued until mid morning on 27th. Brundall recorded the highest total of 8.06" but 7" appears to have fallen in the Buxton area. The Bure overflowed its banks and people had to be rescued from upstairs windows by boat. Animals were drowned, the road to Lammas became a roaring flood and the meadows were one big lake. |

|

|

The

1912 flood with the mill in the distance

|

|

|

|

Buxton

dam after the 1912 flood

|

Buxton dam looking upstream August 1912 |

|

Many hay cocks were swept down from the Lammas & Hautbois meadows causing a damming of the river by the narrow Coltishall Bridge. When this gave way the water levels dropped in Buxton. |

|

|

Coltishall bridge 1912

|

|

The wherry Zulu, was trapped in the river Bure while unloading cargo at Aylsham and as the locks were destroyed it was unable to get back down the river and it had to be manhandled across the road near Buxton Mill. |

|

|

Zulu

being moved across the road near Buxton 1912

|

|

RP - Was 'Zulu' the one that was trapped when the floods

came? |

|

In June 1933 the old lock from the Aylsham Navigation, which had been disused since the 1912 flood was filled up and a good road finally opened from Buxton to Lammas. |

|

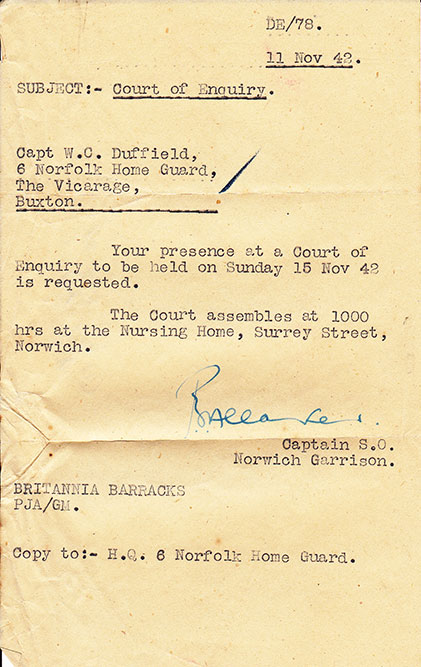

In the possession of Mr. William Duffield. |

|

Letter to Capt. William C. Duffield - 11th November 1942 |

|

Turbine Repaired |

The 60-year old American water turbine that operates the mill at Buxton has just been given a new lease of life by an unusual welding repair. |

|

|

|

20th September 1957 |

December 1958 |

|

Locum removed - c.1963 |

|

Eastern Daily Press advert - c.1965 |

|

|

September 1967 |

|

On 22nd May 1970, due to expansion at Saxlingham, Duffields announced closure of Buxton and Tharston mills As a result Buxton and Tharston Mills were both closed in 1970 enabling production to be undertaken by 9 staff rather than 18. 10 staff at Buxton and 1 at Tharston to be made redundant. |

|

Duffields' Milling History

|

|

1891-1892: W.I. Duffield started milling at the Black

Tower Mill, Mattishall, making stone ground flour. The mill developed

up to 20h.p. 1910: Saxlingham Mill was acquired 1919: Tharston Mill was acquired; Tasburgh and Saxlingham Mills were relinquished, but not for long 1924: William C. Duffield took over the mill at Buxton, remodelling it into a 2½ sacks per hour roller mill 1928: Saxlingham Mill was reacquired 1936: W.L. Duffield & Sons Ltd. was formed 1940: Animal feedstuff compound was first produced at Saxlingham 1950: Duffields acquired the tenancy of Hautbois Hall Farms (176 acres) 1951: Buxton flour mill was remodelled and capacity doubled 1952: Tharston flour mill was remodelled and capacity doubled 1953: Lamas Rectory and and 46 acres of glebeland adjacent to the farm were purchased 1960: The warehouse at Buxton was built 1962: The Duffield Group was formed with Duffield Mills Ltd. as the holding company 1963: A further 123 acres of land adjacent to the farm were purchased 1964: Buxton flour mill capacity was again doubled to ten sacks per hour 1965: The feed capacity at Saxlingham was doubled 1970: Modernisation at Saxlingham,

doubling capacity for flour production despite the closure of Tharston

and Buxton Mills. The group today employs a staff of 109. |

|

|

|

Seed

dressers June 1970

|

Pulley shaft June 1970 |

|

c.1935 with the lucum still in situ |

|

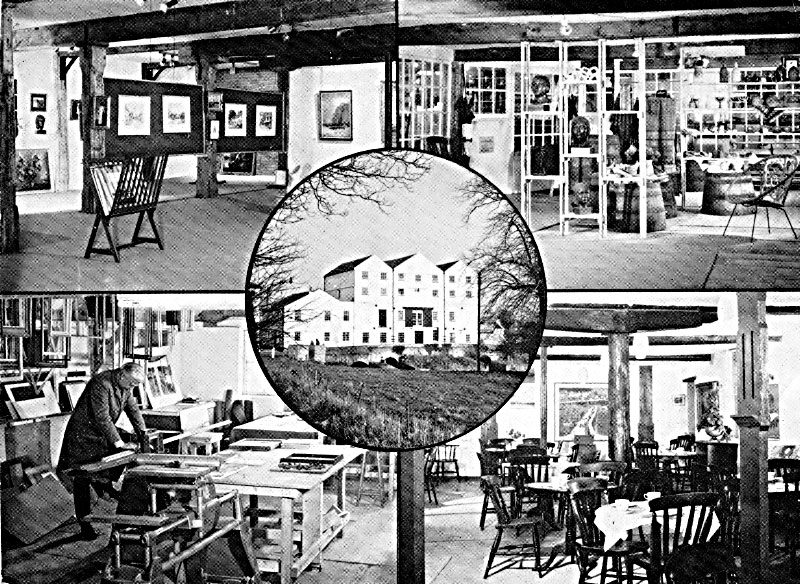

Dreaming of unique arts centre for old mill |

A YEAR AGO last summer Buxton Mill, standing massively over the River Bure at Buxton Lammas, was still producing flour, as it had been doing for two centuries past. |

|

Craft Centre c.1973 |

|

The first part of the Craft Centre opened in December 1971 and the second floor opened in April 1972. |

|

|

|

c.1974 |

23rd April 1977 |

|

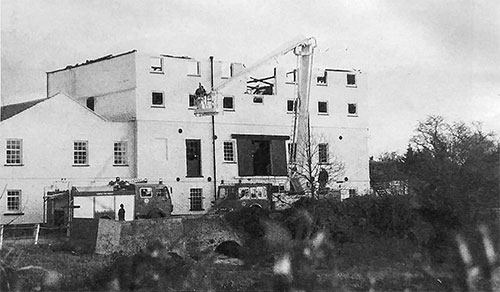

'This is a new 1750s' mill . . .' |

Businessman John McDonnell woke up to a nightmare one winter's morning last year. |

|

|

|

The fire of January 1991 |

|

|

|

|

Aftermath of the fire January 1991 |

|

|

Damping down January 1991 |

|

|

|

Damping down January 1991 |

|

|

A 14-month rebuilding programme followed the fire of 1991, using 19th century North American pitched pine salvaged from across Britain. The largest beams, often more than a metric tonne each, came from as far afield as Scotland and Wales. |

|

Mill back in business after blaze |

Gleaming white, and once more a proud village landmark - Buxton Mill has risen from the ashes of a disastrous fire just 15 months ago. |

|

Millstones set to grind flour again |

Restauranteur Bob Branford plans to bring back the ancient art of milling to Buxton Mill. |

|

The above dream project never materialised, possibly due to the inordinate expense involved. |

|

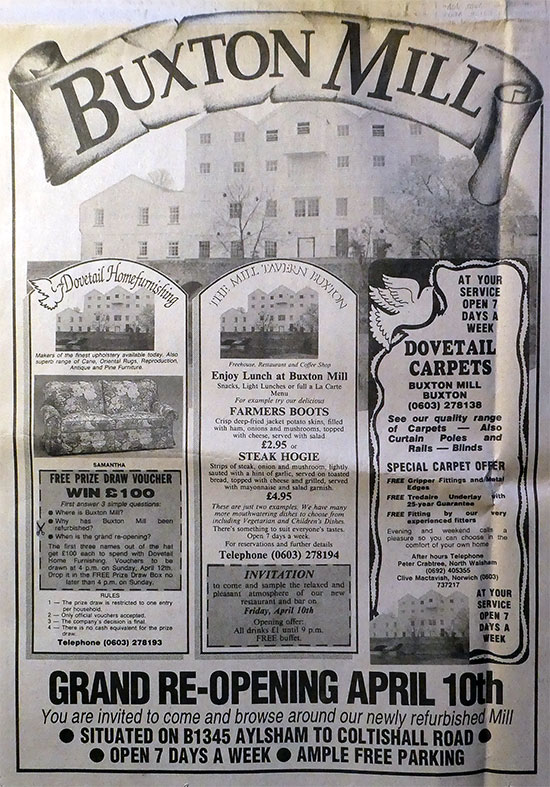

Eastern Daily Press advert - Wednesday 8th April 1992 |

|

Watercolour by John Watson in 1999 |

|

Hotel Scheme Gives Historic Mill New Role |

£350,000 project will turn mill into a 19-bedroom hotel and conference

centre. One of Norfolk's best known historic landmarks which was gutted by fire seven years ago is to be given a new lease of life after a £350,000 revamp. Buxton Mill, which can be traced back to the time of the Norman Conquest, underwent a £1m restoration after the blaze in January 1991 and was subsequently put up for sale at £400,000. Now the mill, 10 miles north of Norwich, is to be converted into a 19-bedroom hotel complete with conference and function room by business partners Bob Branford and Richard Draycott. Mr. Branford said: "We identified a need for a local quality conference and function facility that had character, was well managed and friendly. We are confident that the Buxton Mill Hotel will attract both leisure and business users across all our planned facilities. "The new business will create local employment, both full and part time within the hotel and ensure the building, a well-known and important part of Norfolk's architectural heritage, will thrive and continue to be enjoyed by future generations." Work is expected to start this month with a view to finishing it in October.The country free house and restaurant operation will stay open for most of the conversion period and will be extended by a conservatory over the River Bure increasing dining capacity to 70 people. The work will highlight the mill's historical industrial features such as the early 19th century turbine and the huge Hirst metal frame, now incorporated in the bar area. All public areas will have displays of the history of Buxton Mill and the village of Buxton, creating a heritage centre for locals and tourists. The development includes a lift to all floors housed in a shaft designed in the style of the original grain silos which previously occupied the same exterior position. A new car park will be available across from the hotel and architecturally the mill will look much like it did in the 1750s. Eastern Daily Press - 14th April 1998 |

|

Royal date for revamped mill |

Historic Buxton Mill, which was gutted by fire in 1991,

will be reborn as a hotel next month after a £350,000 conversion and

opened by a "royal personage". The 18th century mill now has a first-floor function suite, a restaurant extension over the River Bure and 14 twin or double bedrooms with river views. A lift to all floors has been concealed in a shaft designed to look like one of the original grain silos. Director Bob Branford said: "We still have a little exterior work to do when the weather improves but the Mill is now looking better than it did prior to the disastrous fire of 1991. "We have designed our facilities to attract both leisure and business users looking for somewhere unique and different. The Mill now offers a range of facilities and services from a quiet drink in the bar to banquets and conferences for up to 100 people. Mr. Branford was tight-lipped about the identity of the "royal personage" saying all would be revealed closer to the opening. Eastern Daily Press - 19th February 1999 |

|

|

Mill Hotel - c.1999 |

Mill Hotel entrance - c.1999 |

Buxton Memories |

As a bored 10 year old boy in 1967 during school holidays, I accompanied my late father (Tom Peck) to work at Buxton mill. No health & safety in those days!

I can vividly remember lots of things from those days like the replacement of drive cogs on the turbine wheel. The vertical shaft from the turbine had a helical gear made of steel around 3 feet in diameter which in turn drove a horizontal gear which in turn drove all the pulley shafts in the mill. The horizontal gear teeth I believe, were made of seasoned apple wood which had to be specially made. The old teeth had practically worn through before replacement. There are three water 'tunnels' running under the mill. One Saturday afternoon during summer, when the mill was stopped and the river was low, my father wound all the sluice gates down at the back of the mill to stop the water flowing altogether (I'm sure the rivers authority would have gone nuts had they have known!) we then donned wellies and walked up the tunnels from the front to see what was up there. Looking from the front of the mill, in the left hand tunnel you could easily see where the old wooden water wheel had marked the wall on each side. At the time I was scared witless, thinking someone would open the sluice gates up. I was assured this would not happen because all the handles were with us at the riverbank! We couldn't see much up the turbine tunnel because the water was too deep. Incidentally, the turbine tunnel looking from the front of the mill is on the right. To control the speed of the whole mill, a vertical regulator shaft ran from the roller floor down to the turbine itself. The speed would be regulated by turning the wheel clockwise/anticlockwise to regulate the water flow. The shaft speed would be checked by hand held RPM counter. There was an adjuster wheel on the roller floor and also at the turbine unit. There were always spare rollers lying on the floor wrapped in waxed paper ready to be fitted as required. The rollers were very heavy and were lifted up by a special lifting device which winched them up to the correct height. The mill was adapted to load flour into bulk flour tank trailers during 1967/68/69. The flour was milled and blown into the tank trailer by pneumatic blower. Because production was slow, the haulier had to stand the trailer hooked up for days while being loaded. Crane Fruehauf built the prototype flour tanker for this work and was hauled by Pointer transport of Norwich at first, then Bartrums carried this on later. These lorries were the very first 32 tonners at the time. Bagged flour and 'midds' would be loaded in the covered loading bay at the rear of the mill near the mill house. 'Bran' would be loaded onto flat lorries parked on the bridge at the front of the mill - busses and other lorries could only just squeeze through the gap between the parked lorry and the bridge wall. Bulk wheat was stored in the first half of the warehouse at the back and transported to the grain intake by an old 4 wheel Seddon bulker - pensioned off from the mill at Saxlingham. The second half of the warehouse was occupied by a Duffield subsidiary called 'Buxton Distributors' - this firm distributed pet foods wholesale throughout east anglia. The old stables which backed onto the river was used as a rest room and toilets when I was there. In the loading bay at the back, a hand crank petrol pump was situated on the right for filling up company vehicles. The staff comprised of only 3 men and a foreman at the time. The only person's name I can remember from then was a man called Keith Mack from Buxton. The phone number in 1967 was Buxton 337. I used to spend days/weeks exploring every part of the mill then, walking up to the shop to buy fruit pies and crisps at lunchtime etc. I never knew if Duffields management knew or cared if I spent all my spare time there - nothing was ever said to me. It was a part of Duffields that was distanced from the main milling activity and while everything ran OK, they appeared to have left it alone. Sadly when the mill closed in 1970, everyone was made redundant and my father, due to an accident in 1971, passed away so, this information I've given you is purely from memory.

Stephen Peck - 16th October 2005 |

|

|

Converted with apartments for sale 7th May 2005 |

|

My grandfather was always talking about Buxton Mill,

because of the family connection and because he worked

for Steward & Patteson's Brewery, which was also in

the grain business one way or another.

One day as a small child I persuaded him to take us all to see the mill. Off we went his is Series E Morris 8, and as usual he went "the pretty way" via all the little back roads. It took hours to get any- where with him at the wheel! Especially as it was a rainy day. Unfortunately just as we were approaching the back end of Lammas we ran into some flooded lanes and hit water every way we tried, except the way we had come. So it wasn't until I had a car of my own that I actually got to see the mill. Local descendant of the Pratt family - 2nd September 2006 |

I have recently been going through our family papers, and have come

across information from the time my Great Grandfather Joseph Parker

owned the Mill.

In 1906 my Great Grandparents held a celebration to mark the refurbishment of the mill, it was combined with the coming of age of my grandmother, Francis Muriel Parker. I have a letter written by the station master congratulating them on the refurbishments. There are some interesting comments in a letter about the quality of the flour and some other details. There is one postcard from around 1906, and we also have paintings of the Mill and canal done by Bernard Wiles (a cousin) from the period my Great Grandparents were there. According to a letter from my Great Grandmother, Fanny Parker, written in 1925, she had sold the Mill due to my Great Grandfather's death. Sue Travers, Victoria, Australia - 9th June 2008 |

|

|

24th August 2008 |

7th September 2008 |

|

18th April 2007 |

|

13th September 2008 |

Buxton Lamas mill was part of the Duffield empire until sold in 1970. This was originally bought and run by W.L.D's son,William C. on his return from South Africa in the early 1920's. I started as manager there in 1969. It was an 8 sack mill (1 ton flour per hour) powered by a water turbine and electricity, all very primitive by today's standards. I can remember the notice under Fire Alarm precautions -- some wit had added "Pray for rain and run like hell"

Simon Cauthery, Australia - 29th September 2011 |

|

The Tharston_mill was run by Harry (HTS) Duffield and was a little gem, 4 sacks/hour beautifully maintained and run by a water turbine and 40 HP Ruston oil engine. These days it would have been kept as a working museum, it was sold for very little money about £7000 comes to mind and Buxton didn't make much. Some of the Tharston machinery went to the Strangers Museum in Norwich. I still have the large wooden pulley wheel from the Buxton turbine shaft,mounted on its side with a glass top makes an excellent coffee table,and an old wooden sack trolley. |

I'm researching my Bean, Beane, Bane, Baine ancestors originating to date from the village of Thorpe Market c.1757. Having a subscription to the British Libraries Newspapers online I've found an article in the 'Norfolk Chronicle' newspaper copy of Saturday 02.03.1833 relating to Mr John Cook Bean of Itteringham, Miller. The article report was of his Deed of Assignment, Indenture dated 26.02.1833 where he Assigned his estate to a John Windett of Plumstead and John Gambling of Buxton, miller. The 'Deed of Assignment' was deposited at the Office of William Repton, Solicitor of Aylsham, to date I'm unsure as to how or if it's possible to obtain a copy of this record of part of his life. Ken Maidens, Lincolnshire - 7th May 2013 |

|

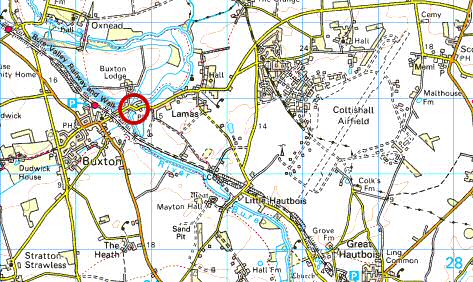

O. S. Map 1880 |

|

O.S. Map 2005 Image reproduced under licence from Ordnance Survey |

| 1654: Date

described as being found on a stone above a doorway in 1960 c.1720: ? Secker moved in from Swafield mill, which the Secker family still owned 1754: Mill rebuilt by William Pepper 1766: William Pepper & Co., millers 1778: William Pepper, miller 1780: William Pepper, miller (1753-1759 at Bawburgh Mill) 1782: William Durrant (at Saxlingham Thorpe Mill in 1778) September 1782: Remainder of mill lease advertised for sale by George Watson, proprietor 1820: Benjamin Richmond, miller (employee) White's 1836: Cooke & Gambling 1838: John Gambling laid claim to machinery at Itteringham Mill Census 1841: John Gambling (aged 50), miller White's 1845: Cooke & Gambling - millers and corn merchants (also at Horstead Mill)

1854: Cooke & Gambling, millers

28th September 1867 - Norfolk Chronicle - Notice re: Sale of Stock... Mr. Gambling giving up mills at Michaelmas

White's 1890: Thomas Shreeve, corn miller & merchant; and Aylsham Kelly's 1916:

J. Parker & Son (Joseph)

1924: William

Charles Duffield took over the mill, which had been derelict for 2 years

1992: John McDonnell, owner; Bob Branford, tenant

and hoping to restore milling function on the premises

February 2005: Bidwells offering 9 apartments for sale with prices starting from £155,000 |

If you have any memories, anecdotes or photos please let us know and we may be able to use them to update the site. By all means telephone 07836 675369 or

|

| Nat Grid Ref TG2379 2288 | Copyright © Jonathan Neville 2003 |