|

|

Painting by James Bulwer - c.1845

|

|

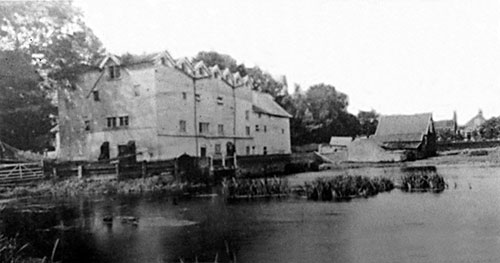

Burgh Mill

River Bure |

|

|

Painting by James Bulwer - c.1845

|

Burgh Mill

was recorded in Domesday in 1085. A brick built mill was erected in the

1500s and further enlarged c.1790, possibly making it the oldest mill

in the county. Parts of the brick section still remain and were utilised

in the new structure and some of the timbers bear ancient markings. Up

until 1980 this mill was reputed to be the oldest working mill in the

country. Apart from the old brick section, the building was mainly constructed

of white weatherboard with a pantiled roof. The roof design was unusual,

having five distinct gables on the western upstream side and six on the

eastern downstream side. The above 1908 photo shows that originally there

was another gable on the southern end but this was removed c.1909. The machinery was renewed c.1828 - according to an advert in the Norfolk Chronicle. |

|

1904 |

|

|

|

1908 |

1928 |

|

c.1930 |

|

|

c.1960 |

1963 |

|

|

Trees centre left mark the possible original mill site |

Part of the new river course March 1967 |

Years ago a Dutchman redesigned the course of the river, the original River Bure lying to the west of the current course. Older mills would have been on the original line were probably built of wood and so are untraceable. Only signs of the ancient road across the meadow gives a clue to the original location. |

|

|

|

Mill Cottage in 1950

|

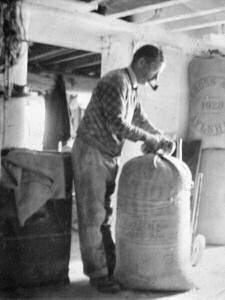

James

Thomas Grix c.1939 |

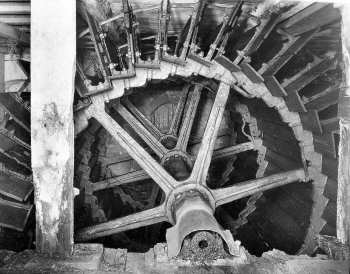

The waterwheel, which is 12 feet in diameter and 9 feet wide, was used into the 1950s to provide power for crushing oats, operating the sack hoist and generating electricity for lighting. A 22hp diesel engine was used for powering the grinding machinery that took over from the millstones. |

|

|

|

Fred Grix with the delivery waggon c.1928

|

Ford

Thames Trader delivery lorry c.1960 |

At

one time Burgh ground corn from America and Russia that had been unloaded

at Yarmouth before being brought up the river in wherries via the 11 mile

Aylsham Navigation. The yellow mimulas that line the river banks inn the

summer are though to have originated from seeds in the Russian barley. |

|

|

|

Burgh lock 1927

|

Burgh

lock 2003 |

Robert Spratt

carved his name and the date on a beam at the top of the mill in 1842. He

also carved a picture of a wherry on the Mill Cottage's privy door, although

it has long gone. |

|

Robert Spratt's name carved in 1842 |

To be Sold, Either together or in Lots, the several following Norfolk

Estates, viz. Lot 1. A Very eligible Farm, consisting of about 212 Acres of Land, and a capital Corn Mill, situate in Aylsham Burgh, upon the new Navigation from Aylsham to Yarmouth, under Lease to Mr John Miller, at the yearly Rent of 160 pounds for the former, and 60 pounds for the latter. For further Particulars apply to Mr Alderman Gay, of Norwich; or to Mr Samuel Wright, at Taverham; or on a Saturday, at the White Hart Inn, in St Peter's of Mancroft, in Norwich. Norfolk Chronicle - 19th April 1783 |

Royal Exchange Fire Insurance policy 122845 |

Willm. Prickard of Burgh near Aylsham in the County of Norfolk, flour Drefser. On his Water Corn Mill including the going Gears & Machinery therein brick, ftud & timber built & tiled situate in Burgh aforesaid - £800. Utensils & Trade therein - £400. 9th August 1791 |

|

2003 |

|

Burgh Mills

TO BE SOLD OR LET WITH IMMEDIATE POSSESSION |

|

An excellent WATER CORN MILL, (capable of manufacturing at least 20

lasts per week), with a convenient Messuage, Granary, Drying Kiln, Stable,

and other requisite Outbuildings, in good repair, situate at Burgh, next

Aylsham, in the county of Norfolk, now in the occupation of Mr. Thomas

Boulter, together with about 13 acres of Land, the greater part of which

is Meadow of a superior quality. |

|

|

The

old privy May 2003

|

A privy was

situated in the corner of the stone floor, it had no bucket and was positioned

to empty into the river directly in front of the wheel... |

| In the 1890s

William Browne & Son owned and ran three wherries: Royal

Charlie, Volunteer and

Oxnead. Burr & Slapp of Burgh also owned and ran the Endeavour, which was used for transporting bricks. |

|

|

Still

in wartime camouflage paint in 1951

|

|

|

|

Mill

dam March 1963

|

Millpool c.1969 |

Occasionally

during the 1800s and even into the 1900s a stock frost would occur in the

winter. At these times the river would turn to ice below the surface with

the water appearing as frozen wet snow. The immobilised river was then unable

to flow through the old lock gates and would overflow into the local meadows

until they appeared as a broad. This phenomena occurred maybe only three

or four times since the 1800s, the last times being in 1947, 1953 and 1996.

The most recent stock frost, the only one Michael Grix (the mill owner) had ever seen in daylight, occurred during Old Year's Night, 1996. On waking in the morning in his cottage by the mill he was struck by the absolute silence. The River Bure had stopped flowing through the lock cut with the sluice gates open, and ice in the lock pool below had formed into circular floating "flan-dishes" up to 24 inches in diameter. Rosemary Tilbrook, Eastern Daily Press, 8th February 1997 |

|

|

The

stock frost of 1st January 1997

|

The first headmaster

of Paston Grammar School (Horatio Nelson was taught there for a time) lived

at the Mill House from about 1590-1610. Sir William Paston himself lived

a little further down the river at Oxnead Hall. |

|

|

|

Dust

extraction March 1967

|

Wheelhouse and wheel March 1967 |

Part of the

1989 - 1990 BBC television series "Campion", was filmed at Burgh

Mill. In the plot the waterwheel killed the villain - a bottle of "blood"

still remains. Also interior shots for "The Mill on the Floss" were filmed there in October 1996, the film location being shared with Bintry

Mill. |

|

|

|

Michael

Grix repairing the wheel c.1952

|

C.R.

Cushion recogging the gearing in 1953 - see below |

|

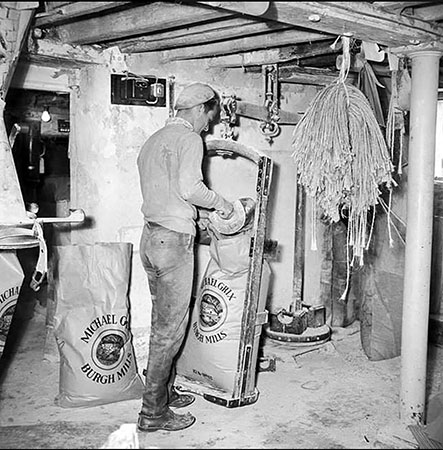

The last miller

was the current owner, Michael Grix who was born in the Mill House and

took over from his father, James Thomas Grix. |

In the early 1950s an artist, Dimitri Kratschkoff was living in a flat in the mill house (he later moved to Aylsham). In 1955, he was visited by his friend Pietro Annigoni and Dimitri later presented him with one of his local drawings, inscribed appropriately. |

|

|

|

March 1967

|

23rd April 1977 |

|

c.1980 |

|

Watercolour by John Watson in 1986 |

|

|

|

Grinding

floor c.1970

|

Ball

governors 1960 |

|

|

Courtesy of the Mills Archive Trust c.1965 |

c.1970 |

|

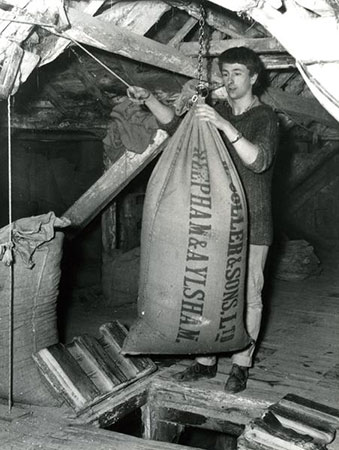

The original building was built on the natural course of the River Bure some two hundred yards south west of the present mill. It used the natural flow of the water to drive a very basic pair of millstones directly coupled to the wheel. In the 16th century Dutch engineers constructed what was virtually a new river. Raising the banks to get an artificial fall, far greater force was obtained from the same volume of water. The power roughly varies in relation to the square of the fall - 2' could give 4 hp, 4' could produce 16 hp. From Aylsham mill pool to Aylsham lock there is a natural fall of 5' and in all probability there was a mill here at one time. To get the fall at Burgh the engineers built new banks, starting by Burgh Hall, lined the bed with clay and on reaching the east end of the village a fall of 4'6" had been achieved. As a result of this alteration to the river the drainage system had to be completely re-designed and this can still be seen today working perfectly (with a little help) after 500 years. The Norfolk Chronicle of 1828 advertised Burgh Mill for sale (or to let) with entirely new machinery. This is I think a slight exaggeration. The 16th century wheel and gearing would have been of all wooden construction. It was not until the 17th century that parts of the wheel and the gearing were constructed of cast iron. In the middle of the 18th century the upright shaft was extended to the second floor. A new crown wheel and pinion with a square cross shaft enabled various ancillary machinery to be driven. A grindstone to sharpen mill bills and a sack hoist to lift the grain up and then be tipped into hoppers to feed the millstones. Burgh's vertical shaft was extended with the aid of a very elementary universal joint consisting of a strengthened collar, held in place with metal wedges. This was a constant source of trouble and was not replaced until the early 1970s when the centres of two large sprockets (which had been exported to Russia) were welded to the top and bottom of the shafts where they connected and series of studs set in rubber provided a slightly flexible drive. The pit wheel cogs were in poor condition at the start of the 20th century but managed to last until 1953 when they were replaced with a new set of hornbeam teeth. Owing to subsidence and unequal wear on the waterwheel bearings the pit wheel and the wallower did not mesh perfectly and the new cogs were put under considerable stress before the fault was discovered and corrected. This set of cogs was stripped in 1985 when running unattended, operating at full power generating electricity for the swimming pool. A new set was fitted (this time at leisure) by Mr. Grix and Peter Gowing using electric tools. The larger (driving) gear wheels in the mill were all fitted with wooden teeth (of either apple or hornbeam) and were fitted with a "hunting" tooth thus making the wear more even over the entire set. The main spur wheel was re-cogged in 1929 and ran every day (apart from Sundays) until 1980 and yet it shows very little evidence of wear. Insurance - The fire insurance on the mill was always high as it had wooden spindle beams (i.e. the mill stone shafts rested on brass bearings located on a heavy wooden support). In spite of the millstones being removed in 1951 and replaced with "hammer mills" premiums could not be lowered. The sack hoist was insured by the corn mill group in the early part of the 20th century. Every year an inspector would come to Buxton station, walk over the fields, inspect the chain for wear and hardening, return to his office in London and post off the yearly bill for the princely sum of 16/8d! Construction - The basic 16th century mill is of brick construction

and over the centuries has been enlarged several times with timber framed

alterations. In 1790 the single gable roof was heightened by a series

of gables running at right angles to the original roof. For some unknown

reason it had seven gables on the east face but only six on the western

side. The southernmost gable was removed in 1907 owing to deterioration.

Two "lucums" were constructed, one over the mill yard for unloading

sacks of corn from the horse wagons and one over the river, for unloading

the wherries, which became navigable in 1797 with the construction of

the Aylsham-Coltishall navigation scheme. The internal sack hoist was

connected to chains running over pulleys and rollers to their respective

lucums. A short pull on the activating rope would quickly bring an 18

stone sack of wheat to the top of the mill (by courtesy of the waterwheel)

but the chain had to be returned manually for the next sack (a real muscle

builder for the arms and stomach). |

|

|

Wheel

1960

|

|

|

|

Wheel

7th May 2003

|

Pit

wheel 7th May 2003 |

|

|

Ancilliary

machinery gearing 7th May 2003

|

|

... and one of our jobs, if the cogs got worn, we had to re-cog the wheel. We preferred to use either hornbeam or beech, and in fact a few years ago Michael Grix of Burgh Mill at Aylsham contacted me, could I re-cog his waterwheel because the BBC wanted to use his mill for one of the episodes in the Campion series, and they wanted the wheels all going round. So I went over, and with Michael Grix we re-cogged the wheel. I even got my photograph in the Eastern Daily Press and the Evening News for doing it. And I got the vast sum of £8 an hour from the BBC for doing it, which is more than I ever earned in my life! And I was told at the end that if I'd have asked for £10 I could have got that. That was quite an enjoyable job. |

|

|

|

Mill

dam 7th May 2003

|

Millpool

7th May 2003 |

|

|

Mill dam 22nd April 2007 |

Millpool 22nd April 2007 |

|

27th January 2007 |

|

18th April 2007 |

|

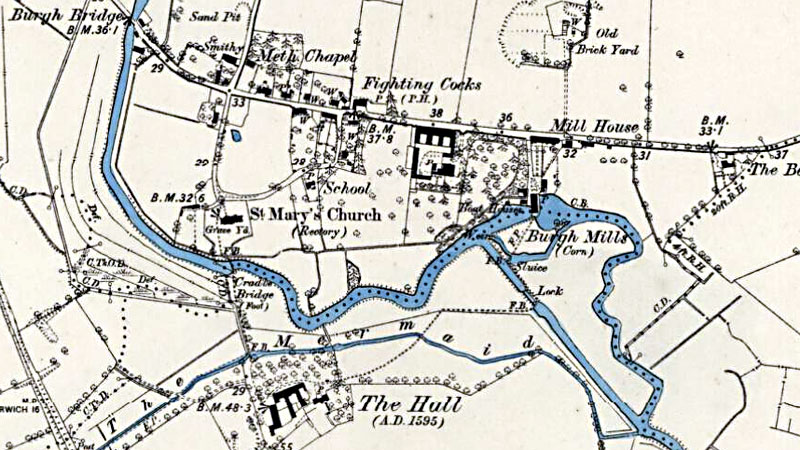

O.S. Map 1885 Courtesy of NLS map images |

|

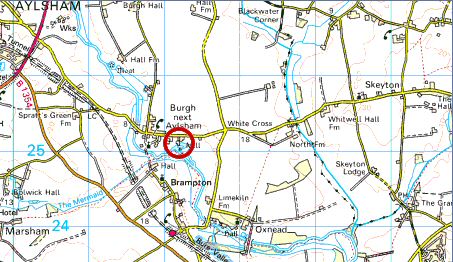

O.S. Map 2005 Image reproduced under licence from Ordnance Survey |

|

Mill recorded

in 1086 Domesday |

If you have any memories, anecdotes or photos please let us know and we may be able to use them to update the site. By all means telephone 07836 675369 or

|

| Nat Grid Ref TG2220 2510 | Copyright © Jonathan Neville 2003 |