|

|

Boardman family visiting - 29th April 1911

|

|

Letheringsett

Mill River Glaven |

|

|

Boardman family visiting - 29th April 1911

|

Letheringsett

watermill was mentioned in Domesday (Leringaseta). The latest structure

was built in 1802 of brick with a black pantiled roof and consists of three

identical gables with a lucum set on the centre one. The windows on both

gable ends have been bricked in. The 600,000 gallon capacity millpond powers an iron wheel capable of driving 4

pairs of stones, two of which are still working. |

|

The

last remaining working watermill in Norfolk - 2023

|

|

|

|

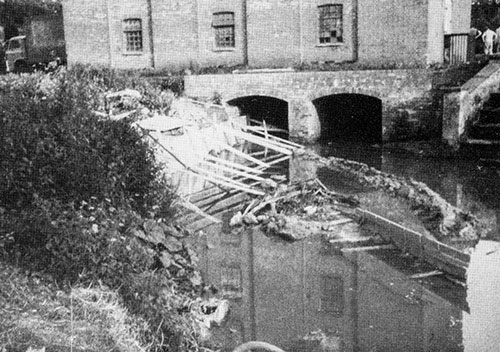

March 1969

|

May 1969 |

|

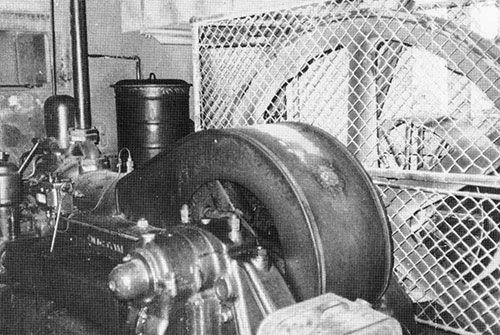

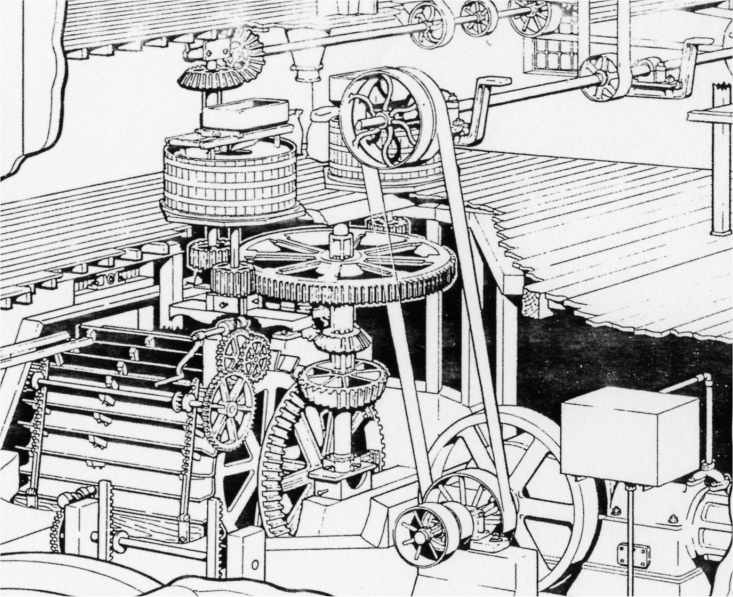

The mill had

a pit wheel and wallower both made with iron teeth. These did not wear

as well as a wood against iron combination and were noisy in running.

Eventually they became so worn that according

to all Engineering Theory they could not drive.

However they carried on running until the system was replaced by a Ruston

Hornsby diesel engine in 1945. |

Mill gear ratios |

| Pitwheel - 96 cogs Wallower - 28 cogs Pitwheel to wallower ratio - 3.4 Great spur wheel - 144 cogs Stone nut - 24 cogs Spur wheel to stone nut ratio - 6.0 Waterwheel to runner stone ratio - 20.6 |

John Priest, who bought the mill in 1744 and also built Letheringsett_postmill in 1754, was the son of Joseph Priest, miller of Sheringham_watermill and a successful property owner. John Priest, however, became bankrupt in 1756 due to his extravagent lifestyle and his properties were then sold off by his assignees. |

Joseph Priest was a miller in the eighteenth century. He owned not only a windmill but also a watermill (Note: There was a watermill at Sheringham at least until 1791 in which year Mr. Bond was assessed at £15 to the poor rate) as well as other property all of which he left at his death, probably early in 1748 to his son Robert who died in May 1771. He made a number of money bequests to his wife and family and he must have been a very successful man. One of his sons was John and he was probably the John Priest who bought a mill at Letheringsett, but he was less fortunate; indeed he later became bankrupt. (Note: Details of this John Priest and his activities are to be found in Basil Cozens-Hardy's History of Letheringsett. For the suit of tithes brought against Joseph Priest see under list of Sheringham vicars (1741) in chapter V, or R. W. Ketton-Cremer's Country Neighbourhood, p.216, from which the account is taken) |

To be SOLD by AUCTION By William Chase from Norwich On Tuesday 28th Day of September next between the Hours of Three & Six of the Clock in the Afternoon, at the Feathers in Holt, in the county of Norfolk. The several ESTATES of JOHN PRIEST of Letheringsett in the said County, a Bankrupt. Lot 1. A Dwelling House, Watermill & eleven Acres of Land in Letheringsett aforesaid, as also a Windmill thereto belonging, part Freehold, & part Copyhold. The Mills are new built & all in the Premises in good Repair. (The said Premises were in the Bankrupt's Occupation) Lot 2. Dwelling House etc. in Letheringsett ... Brewing office ... For further Particulars Enquire of Mr. Thomas Paul of Felbridge, Mr. Nicholas Downing of Holt or Mr. John Beeston of Langham, the Assignees to the Estate & Effects of the said Bankrupt, or to Mr. William Stuart Hawys, Attorney at Law in Fakenham. Norwich Mercury - 18th September 1756 |

|

Postmill drawing - 15th April 2008 |

A faint drawing of Letheringsett_postmill was still just discernable on the internal east wall of the watermill in 2007. |

Letheringsett. Wind grist mill erected about 1754 for John Priest a Sheringham miller, who bought the water-mill estate and brewery. In 1757 his bankruptcy trustees sold the estate to William Colls, a Quaker. Philip Unwin - 1972 |

|

|

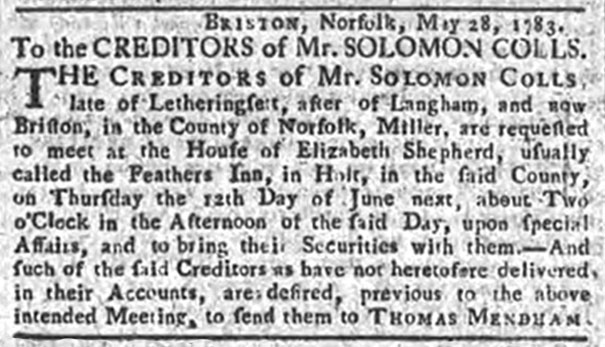

Bury & Norwich Post - 31st May 1783 |

Briston, Norfolk, May 28, 1783. |

The CREDITORS of Mr SOLOMAN COLLS, late of Letheringfett, after at Langham, and now Brifton, in the County of Norfolk, Miller, are requefted to meet at the Houfe of Elizabeth Shepherd, ufually called the Feathers Inn, in Holt, in the faid County, on Thurfday the 12th Day of June next, about Two o'Clock in the Afternoon of the faid Day, upon fpecial Affairs, and to bring their Securities with them. -- And such of the faid Creditors as have not heretofore delivered in their Accounts, are defired, previous to the above intended Meeting, to fend them to THOMAS MENDHAM. |

|

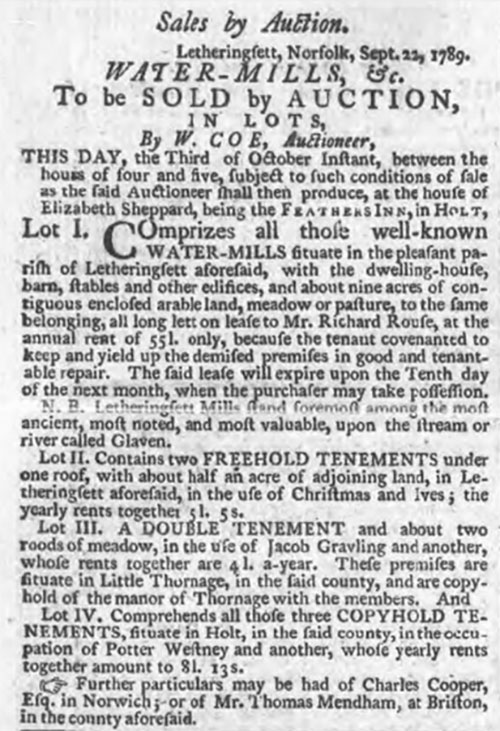

Norfolk Chronicle - 3rd October 1789 |

|

Norwich Mercury - 1st December 1798 |

|

|

8th February 1997

|

|

Working mill days remembered by Peter Gawing, Norwich |

|

|

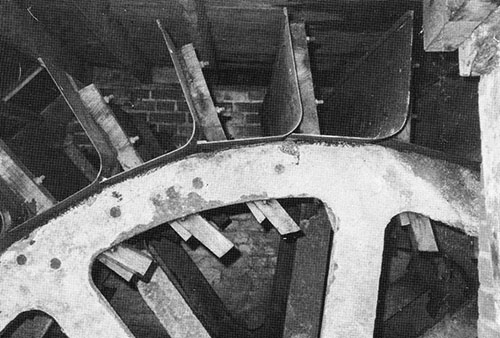

The

waterwheel in March 1969

|

|

In the 19th century the mill dam was raised by 2 feet to increase the flow to the breastshot wheel system. Unfortunately this caused several fields belonging to local farmers to flood. |

|

|

Loading

in May 1969

|

|

There was once a jetty on the upstream side of the mill, which leads to speculation that corn could have been brought by boat in from the coast before the road bridge was built. |

|

|

Headrace

March 1969

|

|

An inscription by the weir reads: This water mark settled in the year 1765 |

Colls Family

The Colls family were Quakers and their Pedigree is entitled: Colls of Burgh by Aylsham, Horstead & North Walsham. |

|

|

|

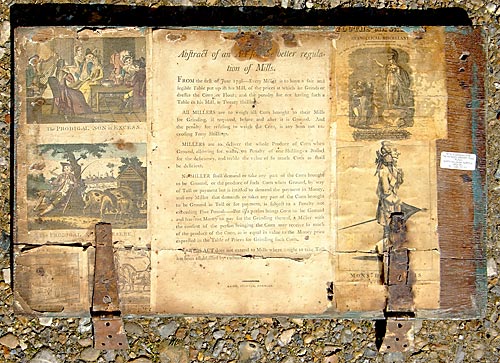

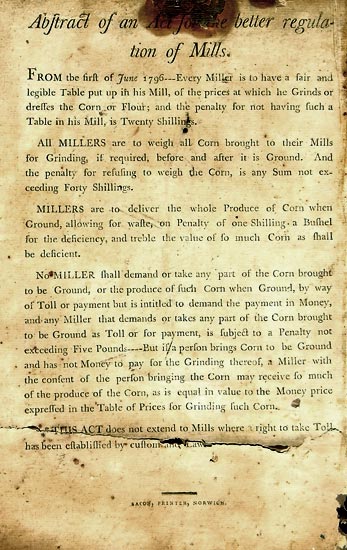

Toybox lid with scrapbook items 15th April 2008 |

New mill regulations of June 1756 found on toybox lid |

|

|

Tailrace 4th February 1983 |

20th September 2003 |

|

5th January

1786: Breach in river bank flooded a meadow owned by Burrell, parson at

Little Thornage 9th January 1786: Burrell refused to let Rouse go on land 16th January 1786: Tenant Lound brought letter to Hardy from Rouse begging to be allowed to make up bank 17th January 1786: Lound showed notice to Hardy's re not allowed Rouse to go on land 20th January

1786: Mr. Rouse threatened Mr. Burrell to make up the Bank in spite Saturday 6th

May 1786: Rouse served Writs on Mr. Burrell our Wm. and severall persons in town on acct. of Mr. Burrell opening the cut that he had stopd up in meadow.

- Mary Hardy's diary |

|

Mr. Rouse set to work his new mill, nearly twice the

building of the old mill or perhaps fully so and calculated for more pairs

of stones. The gates higher or resting on a higher sill than those of

the old mill (according to the testimony of Thomas Dunn and others about

6 inches...) |

|

When Richard Rouse died in 1816 his will instructed

his executors to run and then sell the mill for the benefit of his widow

and daughters. His son, Zebulon who was also a miller and corn merchant,

relinquished all claim on his father's estate in 1826. Zebulon had been

sent to prison in 1801 for debt and no doubt was not in his father's good

books. "Uncle" William Hardy took over the estate in 1797 and

bought the mill for the sum, including subsequent alterations, of £5,000.

He died in 1842, so the alterations he referred to must have been made

before then. It is not easy to deduce what those alterations might have

been, for there seem to have been a number of changes since then. The

mill still remains in "Uncle" Hardy's family today. |

|

|

|

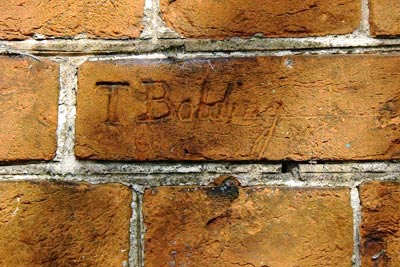

T. Bolding on wall facing mill dam

|

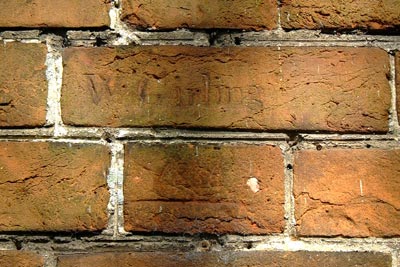

W. Girling 1856 on wall facing mill dam |

LETHERINGSETT MILL |

|

Edward & Edith Cracknell c.1904 |

Letheringsett Estate Trustees commenced a program of major repairs and renovations to the mill and machinery in 1982. David Mayes of the Estate provided general liason, using the advice of millwright Peter Warwick BSc, DFH. |

|

Bank reconstruction below the mill - 1982 |

|

|

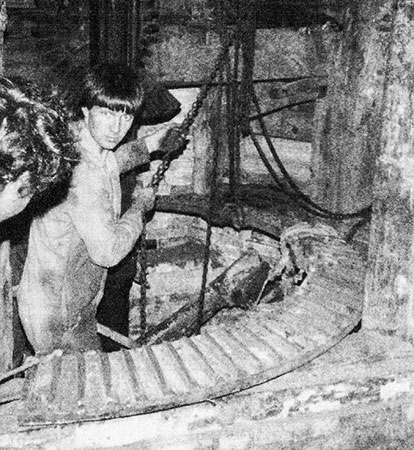

Removal of worn wheel buckets - 1983 Lft to rt - Richard Matthews, John Matthews (at back) Andrew Doy, Robert Matthews |

David May removing the pitwheel - 1983 |

Each of the wheel buckets was 8 feet wide and needed two men to lift them. Of the 32 buckets, 10 were replaced and 22 were repaired. The cast iron pitwheel was cut into segments before being removed for repairs. |

|

New buckets installed with elbow oak wedges bolted to the wheel - 1983 |

In 1984 the millwright, Peter Warwick converted the mill from diesel power back to water power for the first time in 40 years for the Cozens-Hardy estate. |

|

According to

Basil Cozens-Hardy - there are or have been 3 water

wheels, 11 sluices, 1 turbine, |

|

|

The

two working tuns 20th September 2003

|

|

The right hand tun in current use contains a pair of millstone grit composite stones and the left hand tun has a pair of 220 year old French burr stones. The lifting gear to raise the runner stones for dressing can be seen to the left. - 2003 |

|

A horizontal turbine was also used on the Cozens-Hardy Estate on the opposite side of the road to the north. |

|

|

|

Ruston & Hornsby Class HR single cylinder horizontal diesel engine 1983 |

20th September 2003 |

|

Mike Thurlow and the newly restored grain cleaner 11th October 2003 |

|

4th September 2004 |

|

Mike Thurlow began restoring the

mill further in 1987. |

|

Retirement brings little rest for this miller |

For pensioner Mr. Arthur Rayner, of Holt, retirement has brought little respite from his work as a miller. |

|

Restoration is finished |

When Mike Thurlow was invited to "take on" the almost derelict Letheringsett watermill he knew absolutely nothing about milling. Now he is regarded as one of the finest millers in the country - and the mill he has restored so enthusiastically among the finest of its kind. Mr Thurlow arrived in the North Norfolk village near Holt with a 20-year naval career behind him, a spell as a lorry driver and a stint as rescue officer with the Norfolk Broads Yacht Club. "I knew nothing. I am self-taught, getting everything out of books. And I made a few mistakes on the way. But it has been a pleasure doing this, it really has," he said. He began restoration of the mill, which had stood idle for 40 years, in 1982 and this weekend celebrates the last of its four floors to the public. And with tens of thousands of visitors flocking to the mill each year to see a preserved part of working farm history, numerous tourist awards festoon the walls. The mill and it products are regarded as Britain's best in the Bread Book, published by Linda Collister and Anthony Blake, and by Henrietta Green's Food Lovers' Guide to Britain. Mr Thurlow revealed he is having problems keeping up with the demand for his flour - the pre-war species Alexandra - all of which he obtains from nearby Stiffkey Estate. "Within a 45-mile radius we look after six bakeries, three health food stores, three delicatessens, a farm teashop and 14 general stores," he said. Further afield there are three restaurant chains in London and delicatessens at Tower Bridge and Richmond to supply. And he is receiving orders for his goods from a French bakery. This weekend visitors can see for the first time a 1954 Penny and Porter "Winnograder" cleaner working away. It was donated by Henham Hall, Essex, and means the water powered mill is now self-sufficient in preparing, cleaning and milling. "Before the machine was installed wheat would be cleaned elsewhere and that could add £50 to a tonne," said Mr Thurlow. David Blyth, Eastern Daily Press - 28th May 1994 |

|

|

|

Pitwheel

and wallower 11th October 2003

|

Wallower

with the auxiliary drive above 11th October 2003 |

|

Michael and Marian Thurlow had no milling experience when they took on the lease. Michael spent almost all his working life in the Royal Navy as a radar operator and travelled the world 7 times, before being invalided out in 1981. He had to learn all about milling from scratch by reading the few books on milling available and visiting other mills that are still working. Needless to say he has learnt he new trade mostly the hard way - by trial and error! Today the restoration continues with Michael carrying out as many jobs as he can, with professional assistance being provided by Nibbs Rawlings and George Rudd. |

|

|

|

20th

September 2003

|

11th

October 2003 |

|

Mill bypass in full flow when mill not in operation 6th October 2007 |

|

Miller Mike Thurlow, who rescued the building about 17 years ago, has built up a thriving trade in his traditional flour. Today, he supplies his special brand of wheat flour half-way across the world with several tonnes despatched to our Embassy in Moscow, two tonnes to Japan for the health food market and almost 800kg to Hong Kong. It has also been possible to export flour to the United States. Five years ago, he installed another set of stones to double the capacity at the watermill. He has shown that there is a real demand for a quality local product – made and milled from wheat grown in Norfolk. Today, he mills one of the oldest wheat varieties known – spelt wheat. It was known to the Egyptians some 9000 years ago and today, seed from this ancient variety is grown on a farm in the heart of Norfolk for milling at Letheringsett. The flour is sold to eight bakers, 37 shops, seven hotels and bed and breakfasts around the region. Although the yield is much lower than the conventional modern varieties, at about 1.75 tonnes an acre, it is ideal for people unable to eat normal flour, including coeliacs. Farmer David Hill at Bradenham, near Dereham, grows the variety for milling by Mr Thurlow, and some 200 tonnes of wheat will be harvested this year. It produces a very fine grade of flour - perfect for baking quality bread and some cakes. “We can hardly keep pace with the demand. I would like to install

a third set of stones to produce more flour,” Mike Thurlow said. |

On 6th October 2007, the grain floor and bin floor were officially opened to the public by North Norfolk MP Norman Lamb. The newly opened floors being designated as exhibition and educational areas with photographic displays, museum artifacts and video streams. |

|

|

Open Day 6th October 2007 Norman Lamb MP talking to mill owner Mike Thurlow |

|

|

Open Day 6th October 2007 Norman Lamb MP standing talking to George and Hazel Jeffries with Bridget Neville in the foreground |

|

New chapter for old mill as it opens doors to public |

It is the last water powered flour mill to operate in Norfolk and this weekend another milestone was marked in its long and illustrious history. |

MP Norman Lamb opens the new part of the mill pictured with its owner Mike Thurlow |

He said: " There was a bit of an intractable problem but here we are five years later and it is tremendous that it is finally resolved. |

|

Booming demand for miller Mike |

Award winning miller Mike Thurlow has seen demand for his stoneground flour soar as bread prices have surged. He is now producing three-quarters of a tonne of locally-grown flour each day at Letheringsett Mill, near Holt, from milling varieties of wheat grown within a 20-mile radius. "Demand is booming. We can hardly keep pace with the orders." said Mr. Thurlow, who has been running the water-powered mill by the River Glaven for 21 years. He now sells between seven and eight tonnes of whet, which is made into 14 grades including organic and conventional flour, each week. The cost of his wheat has risen over the past year from £175 to £285 per tonne as quality has remained in relatively short supply. "I don't think we're going to see an end to this," he added. He sells a 1.5kg bag of conventional wholemeal flour for £1.85 and stoneground for £1.65. His organic range costs £2.10 and the wholemeal for £2.05 per bag. "Consumers are turning back to our traditional flour which is regarded as among the best in the country." said Mr. Thurlow. Eastern Daily Press - 28th February 2008 |

|

|

Mill staff and new stones 15th April 2008 l to r: Jackie Thompson, Carol English, Peggy Jarvis, Robert Wilson, Paul Booker, Mike Thurlow |

New stones 15th April 2008 |

|

|

Lifting to the stone floor 15th April 2008 |

Stone floor 15th April 2008 |

New millstones were delivered

yesterday to the last working waterpowered

flour mill in Norfolk.

Letheringsett Watermill, near Holt,

received a pristine pair of

grindstones from Holland after

waiting 14 months for them to be

made.

The mill’s other two grinding stones came from derelict windmills and the last were added 10 years ago after they were found in a burnt-out mill. But with a growing demand for Letheringsett flour, miller Mike Thurlow realised that a third set of stones was needed and as windmill cast-offs are designed “upside-down” making them less efficient, he decided to order a brand new set. The new addition, which came with a hefty price tag, were bought thanks to part of a £40,000 prize scooped by Mr Thurlow after he won the Local Food Hero title in a UKTV Food competition last year. As well as the £3,000 new millstones, Mr Thurlow was able to open the top two floors of the 200- year-old building for school parties. Mr. Thurlow - who also won an outstanding achievement award at the EDP Norfolk Food Awards in 2007 - said: “It’s wonderful. It is something that we’ve been working towards for years. We’ve been waiting for this for so long. Demand for our flour has been growing and growing for years. It is brilliant that we’ve got this far.” It was certainly no run-of-the-mill task getting the new stones into the second-floor room. Mr. Thurlow said that in days past, millers used to set aside three days for the job as they had a pulley to hoist them up the side of the building before swinging the weight into the upstairs room. Yesterday it took 1½ hours with a crane as the stones were lifted in and rolled along the floor. The current watermill was built about 1802, but it is thought that a watermill has been on that site since the Middle Ages. Mr. Thurlow and his wife, Marion, fell in love with the mill and decided to take it on - fearing that nobody else would - in 1987. Annabelle Dickson, Eastern Daily Press - 16th April 2008 |

|

|

Miller's clock prior to restoration 7th March 2009 |

Clockmaker Kristian Buller & Mike Thurlow - 25th March 2009 |

In 2009, Mike Thurlow acquired the clock that used to hang in the mill house. At that time the clock did not work, had no glass and was in need of full restoration. Clockmaker Kristian Buller of Frettenham, restored the clock and returned it to the mill on 25th March 2009. |

And then, of course at Letheringsett, we did put the diesel engine in there because the cogs had got so bad. |

Home-baking boom during coronavirus lockdown sparks huge demand for bread flour |

A revived interest in home bread-making during the cornavirus lockdown has helped spark a huge upsurge in demand at Norfolk's only flour-producing watermill. |

Michell Thurlow helping the grain through the hopper which feeds the mill stones |

The team at Letheringsett Watermill near Holt has carried out a months’ work in two days in a bid to satisfy orders from farm shops, delicatessens and domestic bakers – some of which are trying their hand at bread-making for the first time while confined to their homes. |

Letheringsett watermill is the only working watermill in Norfolk |

Owner and manager Michelle Thurlow, who inherited the restored mill from her parents and runs it despite her allergy to flour, has been milling up to 12 hours a day to clear the backlog. |

Michelle Thurlow operating the main sluice gate handle |

“It means people are getting used to our flour and hopefully they will come back and continue to buy our flour once this is all over. You cannot beat home-made bread, so I think a lot of people will carry on baking after this. |

Daughter hopes to develop Norfolk's only working water mill |

Two decades after its restoration, Norfolk's only working water mill has 'floured' into a thriving business.

And now Michelle Thurlow - who runs the 220-year-old Letheringsett Watermill near Holt - wants to take things further and put it more firmly on the map as a visitor destination. Miss Thurlow, 35, said: "I'm trying to make it more of a venue where people can come. "I'd like to have a bakery and a tea room and I'd love a massive play area in the back paddock. I've had a feasibility study done, it's just a matter of finding the funding to do it." Visitors can already tour the different floors of the mill, buy fresh produce from the farm shop, a Fryer's Original Pies stall, and an antiques shop which has just opened on the site. |

Michell Thurlow at Letheringsett Water Mill |

Letheringsett is one of just 24 working water mills in the UK, harnessing the power of the River Glaven to produce 4-5 tonnes of flour a week in the way it has been done for hundreds of years. |

Michelle Thurlow at Letheringsett Water Mill She is pictured with her team, Miller Vic Gerrard and Mill Assistant Jason James Credit: Sonya Duncan |

Miss Thurlow said demand for flour was at its strongest during the first lockdown thanks to the popularity of home baking, and business was steadily growing. She said: "We went from milling 4-5 tonnes every four weeks to 6-7 tonnes a week of flour. "We had some quiet periods through Covid where we did struggle, but now people are coming on holidays again and doing visits." There have been some setbacks - recently a part of a huge milling stone broke, which Miss Thurlow said would cost thousands of pounds to fix. |

Inside the farm shop at Letheringsett Water Mill. Credit: Sonya Duncan |

Pieces from the past: Antiques shop launches |

One of the newest additions to the Letheringsett Mill grounds could be described as an 'Aladdin's cave' of treasures. Mill Antiques and Brocantes has recently opened in a converted stable building on the site by Malcolm Mellor and 30-year veteran of the antiques business, John Overland. Inside, traditional Norfolk chairs sit cheek by jowl with flamboyant Asian furniture, rugs and ornate mirrors. Mr Mellor, who is semi-retired, said: "I've always had an interest in antiques and collecting them, and the opportunity arose to move into this converted barn. "There's everything from a chest which is going for £3,500, everyday collectables like pieces of coloured glass for £10, and everything in between. "It's a totally eclectic mix of items, many things you might never have realised you wanted until you came in here and said 'Oh, look at that'. Mr Mellor said he acquired most of the items in the shop by "private sale or private negotiation". Stuart Anderson, North Norfolk News - 19th June 2021 |

Letheringsett Mill has stopped turning after major breakdown |

An urgent appeal has been launched to raise £10,000 to carry out major repairs at Norfolk's only remaining working water mill that makes flour. |

|

|

Letheringsett watermill's internal layout drawn by Barré Funnell |

|

|

Letheringsett's water and diesel gearing drawn by Barré Funnell |

|

|

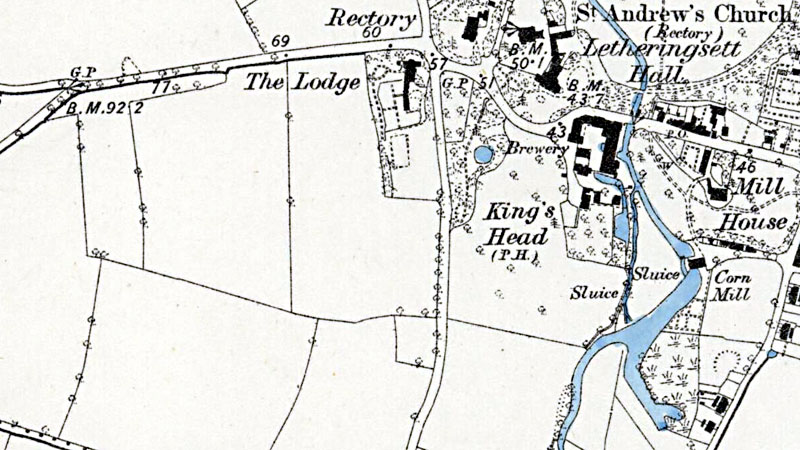

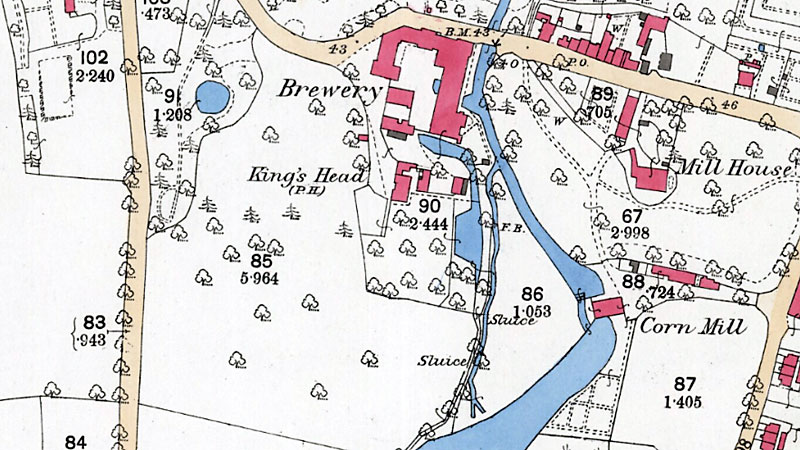

O. S. Map 1886 Courtesy of NLS map images |

|

|

O.S. Map 1886 Courtesy of NLS map images |

Letheringsett Watermill |

1791: Thomas Youngman, millwright, Letheringsett |

| Domesday: Walter

Gifford (Domesday records pairs of millstones not mills) 1383: Thomas de Saxlingham 1384: Thomas de Saxlingham died whilst selling 30 acres of arable land, 8½ acres of pasture and a watermill to John de Keyly and William de Gatel. An order from Westminster was then required to complete. 1550: John Brytwiss - miller 1660: Vincent Buckingham - miller 1714: Thomas Bately, miller 1720: John Brereton owned the mill, the house (later Letheringsett Hall) and the brewery 1743-1744: Mill burnt down

September 1751: William Colls brother, Robert Colls leased Itteringham mill c.1754: Probable time that the mill location was moved approx. 200 yards downstream 1754: John Priest mortgaged the mill "All that now rebuilt water-mill." 1756: John Priest (educated at Free School, Holt) bankrupt due to extravagance 1756: William Colls, merchant of Letheringsett bought mill estate from John Priest after his bankruptcy 1765: Water level agreed with Nicholas Kendall & John Burrell, riparian owners upstream as flood protection. Extant ston on the site inscribed: This water mark setled in the year 1765 1770: William Colls died and his son William inherited the mill 1772: William Colls jnr. died; Solomon Colls (brother and minor) inherited 1777: Solomon Colls (schoolmaster) let mill to Richard Rouse November 1781: Richard Rouse, miller, took out an insurance policy with Royal Exchange Fire Insurance 1783: Solomon Colls bankrupt c.1785: Richard Rouse living in Riverside Farm 1786: Major flood that was cause of a dispute between Richard Rouse and Revd. John Burrell - see above 1790: Robert Colls (cousin of Solomon) sold mill to Richard Rouse and mill farm to Henry Butler Faden's map 1797: Mill 1798: Zebulon Rouse, mill proprietor, London, rebuilt the mill December 1798: Mill advertised to be let 2nd March 1800: Anne Thompson buried, widow of the late William Gunton Thompson of Walsingham, Letheringsett miller 1802: Mill burnt down 1802: Richard Rouse rebuilt the mill after it had changed hands twice more and burnt down yet again 1802: Richard Rouse installed new stones and began working the mill at Michaelmas 11th October 1805: Richard Rouse left Glandford and moved into newly built mill house 1816: Richard Rouse, owner, retired to Brinton and mill being worked by son, Peter Rouse 1816: Richard Rouse died aged 80-84 1826: Richard Rouse's widow Mary Ann (née Fitt) owner, died. Mill being worked by son Peter Rouse 1826: Richard Rouse's 1826: Mill bought by "Uncle" William Hardy of Letheringsett Hall (great great great uncle of Hon. Beryl Cozen-Hardy and brother of Mary Ann who married a Cozens) who eventually spent over £5,000 updating machinery Pigot's 1830: William Cooke, miller, Letheringsett 1830: Peter Rouse died aged 58 1842: William Hardy died White's 1836: Isaac Everett Census 1851: William Girling (35) journeyman miller White's 1864: William Howes Kelly's 1883: Henry Fountain Howes & William Howes Kelly's 1892: William Howes Kelly's 1896: Robert Elias Scott Kelly's 1912: Robert Elias Scott Kelly's 1922: Sydney Stephen Burroughes, also Holt tower mill 1924: Edward Cracknell, miller Kelly's 1925: Edward Cracknell, miller Kelly's 1929: Kenneth Cracknell, miller 1933: Mrs. E. A. Cracknell Kelly's 1937: Mrs. E. A. Cracknell 1940: Ruston & Hornsby diesel engine installed because "... the cogs had got so bad." 1960: T.G.M. Boast. Mill broken into and safe containing little money but historical documents stolen Yates 1966: T. Boast, The Mill, Letheringsett. Ph. 3237 Tel. directory 1970: T.G.M. Boast, grist & provender miller 1972: Aminovit Ltd, animal feed specialists 1973: Animal feed milling ceased 1982: Millwright, Peter Warwick began restoration assisted by David Mayes and Matthews Builders 1984: Water power reinstated 1987: Mike and Marion Thurlow - Mike Thurlow, miller 1987: Mill opened to the public 30th September 1987: Mill designated with a Grade ll listing 2003: Mill one of North Norfolk's top tourist attractions 6th October 2007: Top two floors opened to public as educational centre by Norman Lamb MP 15th April 2008: Pair of new stones delivered from Holland at a cost of £3,000.00 20th June 2013: Mike Thurlow died 2014: Mill being run by Thurlow family 23rd August 2015: Marion Thurlow died September 2015: Mill being run by Michelle Thurlow March 2020: Milling increases from 2 tns wheat per month to 2.8 tns in 3 days due to Coronavirus pandemic 2nd October 2023: Mill flooded at night for the first time since 26th August 1912 - 2 inches of rain in an hour September 2024: Crown wheel teeth stripped requiring a £10,000 refit and repair |

If you have any memories, anecdotes or photos please let us know and we may be able to use them to update the site. By all means telephone 07836 675369 or

|

| Nat Grid Ref TG 06213870 | Copyright © Jonathan Neville 2003 |