|

Paston

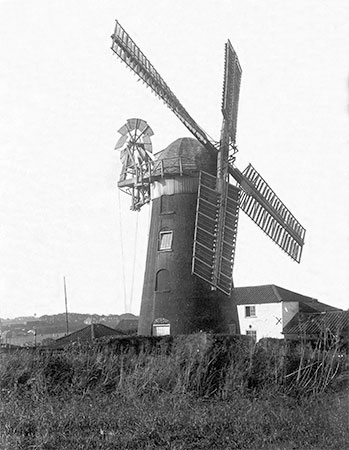

Stow Hill towermill |

|

|

c.1890

|

|

Stow mill, situated on Stow Hill in Paston on the coast road near Mundesley, is often known as Paston mill. The imposing 4 storey towermill was built as a flour mill in 1827 and was unusual in that it was designed from the start to look scenic, even to the extent of having dummy windows on each of the upper floors. The tower was originally white-painted, as the two older photographs show. Around 1850 a steam mill was added that drove a further 2 pairs of stones using a 5 h.p. engine. |

|

The tower originally had opposite doors on the ground floor, although one was bricked up in later years. Two blind windows were set into the tower on the 1st, 2nd and 3rd floors. The mill used 2 pairs of double shuttered sails struck by lever, one pair having 8 bays of 3 shutters and the other 7 bays of 3 shutters. The 12 sided domed cap was horizontally boarded and had a petticoat, gallery and a left handed, 8 bladed fan. The brake wheel was made of wood and had a clasp arm. |

|

In the 1980s Rex Wailes provided Harry Apling with some technical information: |

The Origin of the name “Stow” |

In 1113 William de Glanville founded the Bromholm Priory at Bacton a distance of 3 miles from here. |

Stay awhile and rest |

| Plaque at Stow Mill - 2004 |

Notice re |

Thomas Gaze snr died in 1805 and passed the property to his son Thomas Gaze jnr who in turn passed it to his son James Gaze who, being desirous of making provision for his said son in order to advance and prefer him in the world leased the property to his son Thomas Pleasants Gaze. Thomas had already built the mill on his father's land, presumably with his father's financial assistance. The lease was for |

Thomas Gaze then took out a mortgage of £900 from Christopher Shephard of Heigham to acquire

the mill, house and land along with |

The property was insured for £800 and in 1828 Thomas took out an additional mortgage of £150, also from Christopher Shephard to finance the building of the mill granary. |

|

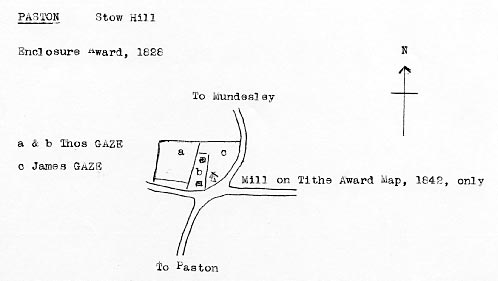

Enclosure map 1828 - as redrawn by Harry Apling |

Enclosure Award & map |

Tithe Award 1842 |

||||||

No. 265 |

House, Mill, Yards & Garden |

|

0a. 1r. 10p. |

7d. |

||

|

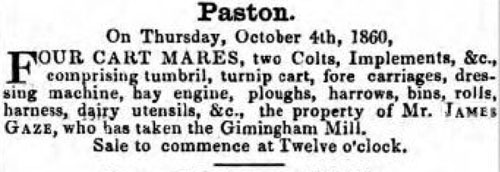

Norfolk Chronicle - Saturday 22nd September 1860 |

GAZE - On the 5th inst., in his 84th year, after a few hours' illness, Mr. James Gaze, many years a respectable farmer, at Paston, in this county. |

|

|

c.1890

|

|

MUNDESLEY AND PASTON |

To be sold by Auction by order of the Executors of Thomas Gaze deceased by Mr. Thomas Barcham on Thursday 3 July 1873 at the King’s Arms Hotel, North Walsham at 6 o’clock. lot 1. A BRICK TOWER WINDMILL in Paston in capital repair driving two pairs of stones, with flour mill, jumper and all necessary tackle and gear. Also a STEAM MILL erected a few years since driving two pairs of stones with the five horsepower Engine and apparatus thereto belonging. Also a comfortable Brick and Tile RESIDENCE with the Granaries, Stable, Cart lodge and Outhouses thereto belonging - Freehold. The Mill is now doing a flourishing business. Possession at Michaelmas next. Apply to Mr. Wilkinson. Solr. North Walsham or the Auctioneer, Mundesley. Norfolk Chronicle - 14th June & Norfolk News - 14th & 21st June 1873 |

Thomas Pleasants Gaze, deceased |

|

|

|

Hand

coloured postcard c.1900

|

c.1924 |

|

|

|

c.1927 |

c.1927 |

|

|

c.1928 |

|

|

|

1928

|

Mrs

Bell (aged 48) and Rock outside the mill 18th June 1933 |

|

c.1940 |

Sails (mock) revolved in gale 2 April 1973 |

|

The Country Scene |

"During some thirteen decades this tarred, brick-walled wooden-capped tower mill has dominated Stow Hill on the Norfolk coast road ..." It has been the writer's recent experience to become sole inhabitant of a converted windmill notable for an exterior not greatly altered from its original condition. Its sails no longer turn, but their size and outline emphasise a landmark locally familiar since the reign of George IV, and today a picturesque piece for canvas and camera alike. Comparatively small windows face rockery and rose garden respectively. Three round rooms - one on each floor, excluding the topmost space (beneath the windshaft) now serving for water storage - are larger than appear from outside dimensions decreasing as one climbs stout communicating ladders wisely railed. Despite not infrequent buffetings of wind and rain, all stands firm - the walls are over two feet thick! An unusual but comfortable home with "modern conveniences", which never fails to intrigue visitors. During some thirteen decades this tarred, brick-walled, wooden-capped tower mill (the third and final type known in England) has dominated Stow Hill, on the Norfolk coast road, looking northward across to adjoining Mundesley, and just inside Paston parish. Its predecessor, on another hill in the western part of that parish was bought early last century by the then miller's apprentice, James Gaze, after his master's death. Moving to Stow Hill, he had the existing building put up and fitted with much of the tackle brought with him. Such was the inference when, on being stripped with living memory, the tackle proved considerably older than the mill containing it. Some was of sufficient value to be preserved in a museum (not yet traced). Paston Mill remained in the Gaze family for two generations, and in 1906 was leased by a new owner to Mr. Thomas Livermore, the last miller. Many still remember these premises to their heyday, as grinding did not cease there till his retirement nearly 25 years later. Conversion into a dwelling was effected soon after 1930 since when the property has seen various occupiers. It is, however, thanks to the efforts of Mr. Roland Bell and his wife (a member of the Mack family who long owned Paston Hall) that the windmill escaped demolition and was reconditioned to maintain its watch over windswept acres within sound and sight of eroding sea. The original miller's cottage adjoining was substantially enlarged by these owners, who further added to an old brick-and-tiled outbuilding at the back, remarkable for solid internal timber including masts as main supports for the loft. Here was housed a steam mill, two places thus being available for grinding. This now echoes - more gently - to the clack of the loom and the song of the shuttle. One craft has yielded after long lapse to another, and the miller's grist has been replaced by the weaver's grist (otherwise the thickness of the thread used). A survival of bygone industry, apart from certain gear immediately under the sail cap, (retained to help with the securing of the sails), lingers in massive mill stones of granite which flank a black knockered, white painted door. Others serve more practical purpose - doorsteps! A praiseworthy example of stonecutter's skill, the sections exactly fitted and held together only by circular steel bands. The best quality stones used to be imported from France but these are not so far identified. The windmill can claim neither the antiquity nor the fame of Alphonse Daudet's mill in perfumed Provence, and in place of his mournful owl one hears cheerful chatter from sparrows which colonise the top storey, but savour no more the scattered grain that must have delighted their forebears. These few notes cannot, of course, emulate the charm of the Provencal "Letters" (a school memory perhaps for many), but are simply meant to depict a pleasant retreat amidst unspoiled land - and seascape. Ideal setting, also, for exercising an ancient craft, which, intimately linked to the cloth trade, was once a source of great prosperity for East Anglia, this county in particular. Interesting to reflect, as the worsted thread races to and fro, that only a few miles southwest lies the village which in its prime gave birth and name to this fine cut from the fleece. A far cry indeed from the atomic age to the 14th Century when Clement Paston - the site of whose home is in the neighbourhood - "rode to mill on the bare horseback with his corn under him." The lane crossing the road by the gate known in good Norfolk tongue as the Yarmouth Loke, led formerly to a highway long engulfed by the waves. For centuries traffic has passed over Stow Hill where, records relate, there was a medieval chapel, possibly a hallowed halt for Walsingham an Bromholm pilgrims. Now, swifter and noisier means of transport prevail, with only occasional clop of hoofs to recall the more leisured - and more arduous - travel of the past. Yet, in the less busy hours, the scene remains essentially the same as always - far flung fields and twisting tracks "in peace under an English heaven." Eastern Daily Press - Saturday 9th November 1937 |

Comments re Reginald Preston's article in EDP 9th November 1937: |

|

|

c.1960

|

|

c.1960 the property was bought by Northamptonshire businessman C. M. Newton. In 1971 the mill was conveyed to C.M. Newton’s grandson, Mike Newton, who enlarged the barn behind the mill and converted it to his home. With the help of admission fees and fundraising appeals he undertook the maintenance of the mill and with substantial restoration it returned the mill to its former appearance. |

LEASE |

|

23rd October 1970 |

|

|

|

c.1961

|

August

1974 |

|

In 1980 the skeleton fantail was replaced by a fully working version and repair work was carried out to the curb castings enabling the cap to turn to face the wind once again after fifty years fixed facing South. The sails were then also able to turn on a windy day, even though they lacked the shutters that would have been fitted when the mill was working. |

|

1989 |

|

|

|

Wallower

and gearing 6th June 2004

|

Stones

6th June 2004 |

|

On 30th May 1983 an

upright shaft, wallower and crown wheel were installed, having come from Houghton

mill in Bedfordshire. Other parts were also salvaged from derelict mills but were never installed including two pairs of millstones from Nedging

Tye, Suffolk. The sails and the stocks that carry them were also replaced. One pair of the replaced sails originally came from Hellesdon_Press_Lane_towermill in Norwich when it was demolished in 1920 but they had to be shortened by two bays in order to fit. The new stocks were made from galvanised steel, which it was hoped would prove far more durable than the previous Columbian pine ones. The exposed position of Stow Mill and the salt air resulted in the need for extensive repairs and maintenance from the 1980s onwards. |

|

|

|

6th June 2004

|

9th March 2009 |

How the mill worked |

Stow Mill is a four-storey tower mill built of brick which is tarred for weatherproofing. Although all the interior machinery below the brakewheel was removed in 1930 the drawing overleaf shows how it was probably arranged. The sails are the most obvious feature of a windmill but they are only effective if they are facing the wind. The cap is therefore arranged to turn on the curb on top of the tower. It is driven by the fantail which rotates if the wind is blowing from one side or the other and this motion is transmitted through gears to a rack and pinion, rather like the steering on a car. The mill has four sails which when working were fitted with shutters, as can be seen from the cover photograph. These could be opened or closed, like the slates of a venetian blind, to allow for variations in wind strength. They were controlled automatically by the ‘spider’ mechanism which was operated by the striking rod and lever. The weight hanging down at the rear could be altered as required to balance the wind pressure. The sails are bolted on two long arms called stocks, enormous beams 52 feet (16m) long mounted at right angles to each other. These were originally made of pitch pine but because of the poor quality of new timber they are now made of steel, galvanised to resist corrosion. The stocks are carried on the cast iron wind shaft and as the sails rotate this turns the huge wooden brake wheel which is fixed to it. This brake wheel originally had teeth of apple wood but many were missing — the remainder have been sawn off in preparation for a new set of cast gears. Around the brake wheel is the brake itself, again of wood and operated by a lever inside the cap The cast iron curb consists of U shaped sections with the rollers between them. The weight of the cap should be evenly spread over the 16 rollers but the cap frame has distorted over the years and the extra load has caused problems with some of the castings. A steel plate has been put in under the main beam instead and this copes more satisfactorily with the unequal stresse The brake wheel is connected to a smaller cog wheel, the wallower. This wallower, the upright shaft which is driven by it and a crown wheel beneath were installed recently, having been salvaged from the derelict mill at Houghton, Bedfordshire. Some variation from the original layout has had to be allowed here as the shaft had to be put in through the doorway and this limited its maximum length. The sacks of grain were raised to the top floor by a hoist driven by the crown wheel. The grain was tipped into bins from which it was fed into the hoppers or shoes for the millstones on the floor below. There were two pairs of millstones, very similar to the ones displayed on the ground floor, which were enclosed in octagonal wooden ‘vats’. They were made of a hard stone quarried near Paris, hence known as French stones and were reckoned to be the best for flour milling. Only the upper (runner) stone revolved, driven by the great spur wheel below. The bottom (bed) stone was stationary and the small gap between the stones was carefully controlled by a ball governor to maintain the fineness of the flour. When the speed of the sails increased the top stone was brought a bit closer to the bed stone by the action of the ball weights. There was a rotating drum sieve on this stone floor known as a bolter which was given to the Science Museum when the mill was dismantled. Unfortunately the woodworm went with it and it has since disintegrated. The ground floor is where the flour was bagged up as it came down chutes from the stones above. The great spur wheel was probably set in the ceiling here, with the stones ‘underdriven’. The display cabinet is set into what appears to be a second doorway. Possibly this second entrance was needed when the mill was first built and fitted with longer cloth-covered sails - if the normal one proved too hazardous because of the sails passing in front then there was an alternative! |

3 Bedrooms,

3 Receptions,

2 Bathrooms |

An update on the external restoration of Stow Mill, Paston. Whilst Roger & Andrea Hough have been busy putting the finishing touches to the inside of the Mill (which is now a holiday let), I have been busy repairing the four Sails. I have restored the Striking Gear, produced new Steelwork to hold the Sails in position, built a new Fantail and are in the process of preparing the new Fanstage. The new Oak sections to repair the Cap Framing have arrived at the workshop in Essex and just last week the restored Sails, new timber Clamps and a new oak Weatherbeam have been delivered to the Mill. The real fun will start next spring when the Cap will be lowered to the ground (the first time this has ever been off since the Mill was built in 1830).The work in repairing the Cap will take around 6 months and once completed, put back on the Tower. The Curb track on which the Cap turns will need some repair work as will the Gearing from the Fantail, but when back in position, the Cap will turn to face the wind. The new timber Sail Stocks (which were delivered last July) will then be cut & prepared, ready to mount the Sails on. It is hoped that Stow Mill will then be seen turning regularly-hopefully for many years to come. |

|

30th March 2018 |

|

|

29th May 2019 |

1st June 2019 |

|

|

7th February 2020 |

7th February 2020 |

|

|

16th March 2020 |

16th March 2020 |

|

|

New stocks - 1st June 2020 |

|

A successful day at the office. The Cap of Stow Mill Paston was back in its rightful place by midday. My sincere thanks goes out to the team from Wavetrade crane hire once again. The weather was perfect for the lift, approximately 20-30 spectators watched the crane effortlessly lift the Cap (weighing exactly 8 tonnes) back onto the Tower. The Curb Rollers all lined up within the Track and the Drive gear from the Fantail engaged first time. The Cap seems to turn incredibly easily by hand and once the Sails are back in place, the Fantail will keep them facing the prevailing wind automatically. |

|

|

16th March 2020 |

16th March 2020 |

|

|

5th June 2020 |

10th June 2020 |

‘It has been a privilege’: |

The owners of one of Norfolk’s landmarks are selling it for £1m after years of work to get its sails turning again. Roger and Andrea Hough tried to sell Stow Mill, Paston, near North Walsham, back in 2013 after buying it in 1999. Their dream was to see the sails of the windmill, built in 1825-27 to make flour, turn again and to preserve it for the future. When potential buyers were put off the prospect of the major restoration required, the couple decided to take it off the market and do it themselves. They are now selling it in full working order and financially viable after converting the mill into a one-bedroom holiday let. Mr Hough told this newspaper: “The reason we are now selling is because my wife and I are both over 70 years of age and we feel that it is the right time to ‘let go’ and hand over Stow Mill to someone younger. We have done our bit, we think. We have looked after Stow Mill for 21 years and it has been a privilege. “The windmill is now in a very good and sound state throughout structurally and restored again to working condition. This does not mean it can now once again produce flour, but it means as a windmill it functions automatically by wind power. This is the absolute requirement for windmills and it is the first time this windmill is able to do this for nearly 100 years.” Windmills are a major part of Norfolk’s heritage and landscape but expensive to restore; recently a historic windmill in Dereham failed to secure £400,000 in funding for repairs. Mr Hough said: “It has taken us nearly five years to complete the transformation of Stow Mill and that was after many years of trying to find ways to give the mill a viable future. Initially, we tried to keep it as a mill open to the public. We provided a service with a shop, parking and access into the mill for a small voluntary fee. “The conversion of the mill to a holiday let and the restoration to working order has cost a great deal of money. It was not a case of a few thousand pounds, by any means. The mill remains unspoilt structurally, it works and now provides an incredible living space. It can now provide for itself financially.” Agents William H Brown are selling the property which includes a three/four bedroom cottage and the windmill. They describe it, saying: “This is a rare opportunity to purchase not just the landmark building but a successful holiday let in a delightful part of North Norfolk.” History of Stow Mill The mill was built as a flour mill between 1825-1827 by James Gaze. There was another mill at Paston, a smock mill owned by Thomas Sadler, but it was demolished in 1840. James Gaze’s son Thomas was the miller at Stow Mill for 45 years until his death in 1872, and the mill was taken on by his son William, who milled until he died 1906. It was unusual in that it was designed from the start to look scenic, even to the extent of having dummy windows on each of the upper floors. It was bought by Ann Harper and taken on by tenant Thomas Livermore, who worked in it until 1930, when milling came to an end at Stow. It passed through a number of hands including, briefly, Norfolk County Council, but efforts to restore it to working order proved too expensive. A comprehensive history of the windmill can be found at the www.norfolkmills.co.uk website. Caroline Culot, Eastern Daily Press - 12th October 2020 |

|

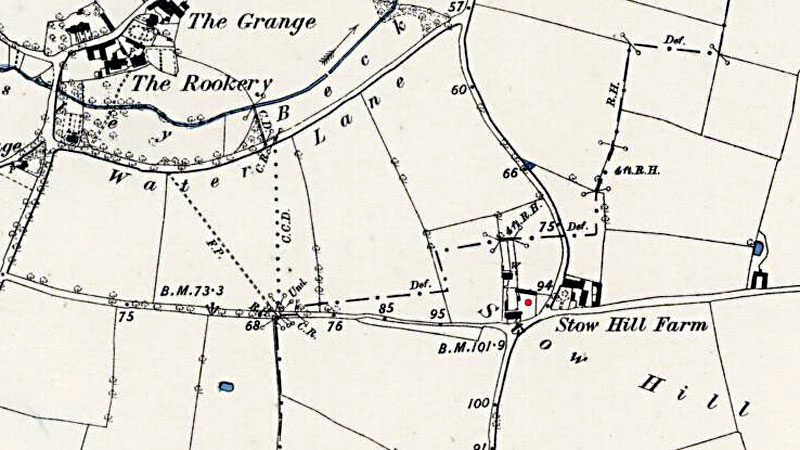

O. S. Map 1885 Mill is the red dot at the Stow Hill Farm junction Courtesy of NLS map images |

Paston smockmill once stood some 1¾ miles to the south of Stow mill. |

|

Title Deeds 28th January 1778: John Taylor, yeoman, conveyed property to James Gaze, gentleman

Deed 1827: Mill mentioned but was not shown on Enclosure Award of 1827

c.1850: Auxiliary steam power installed to drive two additional pairs of stones Tithe Award 1842: Owner & occupier: James Gaze jnr.

17th June 1906: William Gaze died

1926: Mill working

1971: C. M. Newton conveyed mill to grandson C. M. B. (Mike) Newton

1980: Skeleton fantail replaced by fully working version. Repairs allowed

the sails to once more turn into wind

July 2011: Mill advertised for sale by John D. Wood & Co. for £550,000 2013: Mill advertised for sale February 2015: Mill advertised for sale for £495,000 August 2018: Sails, fantail and cap renovation well under way with view to allowing the sails to turn once more February 2020: Cap with windshaft beside mill waiting for installation 16th March 2020: New cap lifted into place, now awaiting fantail and sails 1st June 2020: New stocks fitted 5th June 2020: New sails turning with wind power October 2020: Mill advertised for sale for £1 million |

If you have any memories, anecdotes or photos please let us know and we may be able to use them to update the site. By all means telephone 07836 675369 or

|

| Nat Grid Ref TG 31623579 |

Copyright © Jonathan Neville 2004 |