|

|

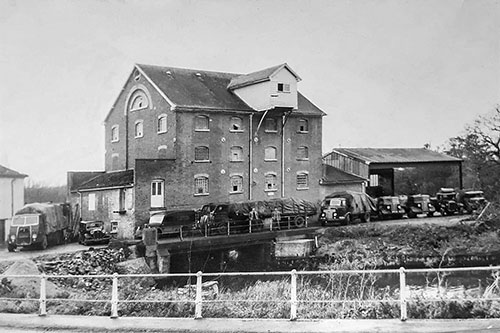

Mill with steam chimney in situ - 1939

|

|

Saxlingham Thorpe

Mill River Tas |

|

|

Mill with steam chimney in situ - 1939

|

|

Saxlingham Thorpe (sometimes know as Newton Flotman, as part of the site lies in that parish) watermill was one of the few working mills left in Norfolk in 2003, being owned and run by Duffields. In its heyday of waterpower in the 1800s the mill wheel drove 3 pairs of stones and three flour mills. |

|

|

c.1912 |

1951 |

|

|

|

July

1967

|

July 1967 |

|

In 1804 Saxlingham Thorpe mill was being worked in conjunction with the nearby postmill but by 1838 this had been rebuilt as Saxlingham Thorpe towermill. |

|

Plan of estate,

property of the late George Watson, esq., table of reference to distances,

windmills, watermills, tollgate house and site of manor house, premises

and gardens marked. |

|

|

Rebuilding

July 1970

|

|

Notice re:- |

Water & Wind Mills, Norfolk |

Such persons as stand indebted to the Estate & Effects of Dennis Wright of Saxlingham in the county of Norfolk, Miller to pay the same to Mr. Wright, Caldecote, Mr. Beverley, of Tibenham, Mr. Forster at Lenwade_Mills in Norfolk, at the Mills at Saxlingham or to Messrs. Foster, Son & Unthank, Norwich otherwise they will be sued. |

Dennis Wright's Debtors |

Commissioners in a commission of Bankrupt against Dennis Wright of Saxlingham, Miller, dealer and chapman to meet 12 August next ... |

Notice re:- |

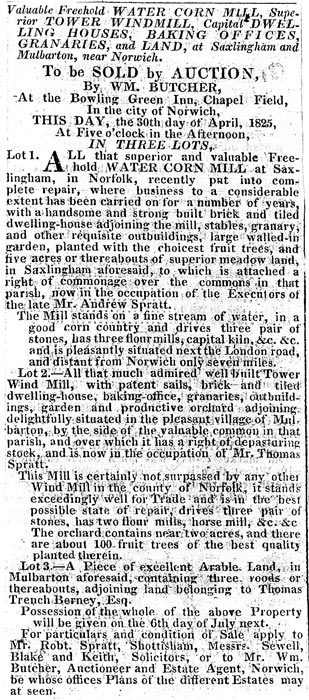

Valuable Freehold Water Corn Mill, Superior Tower_Windmill, Capital Dwelling House, Granaries and Land at Saxlingham and Mulbarton. |

|

Norfolk Chronicle -

9th, 16th, 23rd & 30 April 1825 |

Mr. BUTCHER announces to the Public that he has received instructions to submit to Public Competition at the Bowling Green Hotel, Norwich on Saturday 26 May, 1838, in lots. |

| To MILLERS |

|

TO MILLERS |

|

Andrew Spratt was baptised on 5th September 1779 He died on 6th September 1823 aged 45 and was buried on 14th September 1823 in Mulbarton. His wife, Rachel Spratt was also buried in Mulbarton. |

To Millers & Capitalists |

To Millers and Capitalists |

To Millers |

Capital Estates and Corn Mills at SAXLINGHAM near Norwich |

Dissolution of Partnership:- |

Candler Family |

Edward Candler, 1811 - 1888 was recorded as miller at Bawburgh in 1836 and 1845. His family were Quakers and several of his relatives were also millers. Lawrence Candler 1747 - 1820 was recorded at at Cringleford in 1806 (either the watermill or the postmill). His son Lawrence jnr. 1773 - 1824 was recorded at Cringleford_watermill in 1836 and again in 1845 with Horatio (his brother?). Horatio was again recorded there in 1864 and his son Horace Robert from 1883 - 1908. Lawrence and Horatio were recorded at Saxlingham Thorpe watermill from 1845 - 1863; they were also running Saxlingham_towermill in 1847. In 1879 and 1883 Horace was also recorded at East_Harling_watermill, where he lived and from at least 1890 - 1896 he was also running Keswick_watermill. |

Valuable Steam, Water and Wind Mills with neat Residence, Cottage, offices and Land at |

|

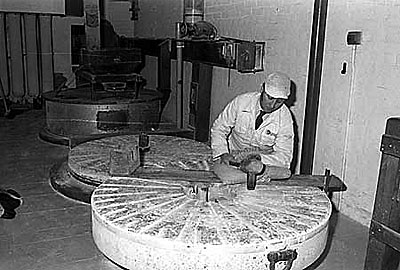

Tony Watson stone dressing, September 1975 |

|

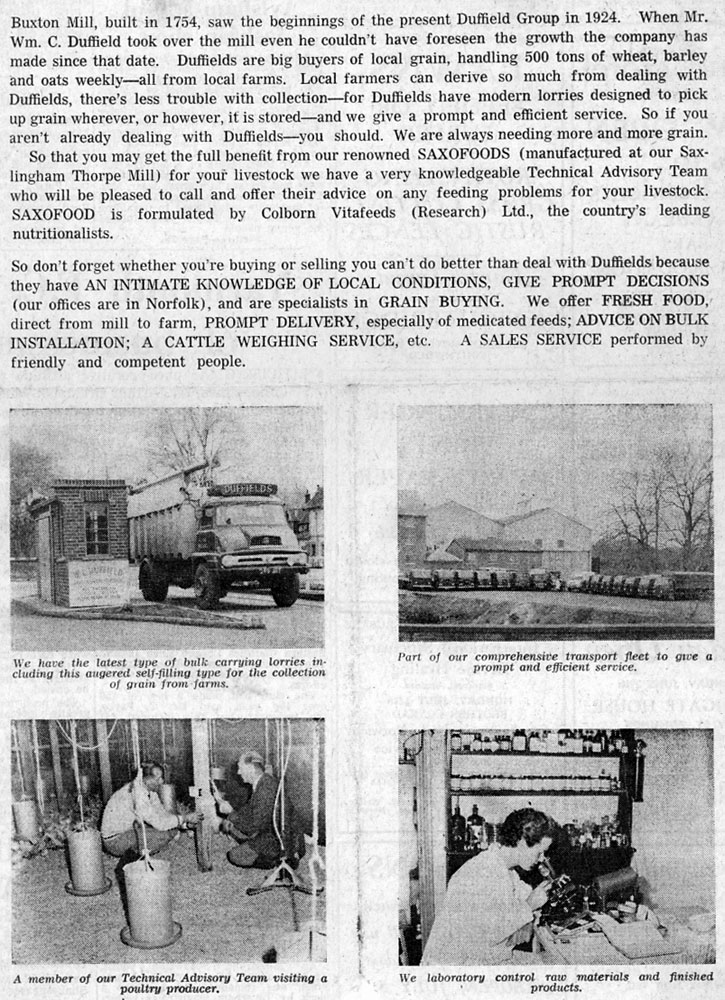

Eastern Daily Press advert - c.1965 |

|

|

|

April

1977 showing the gable end of the old mill

|

April 1977 |

After torrential

rain on 16th September 1968, the whole of the Tas valley flooded and covered

a vast area including the area around the mill. While the Anglian Water

Authority were realigning the river course on both sides of the new road

bridge, Duffields took the opportunity to fill in the watercourse cut from

the river Tas that was originally used to provide water to power the mill.

It took six thousand cubic yards of hardcore to block the old waterway. |

|

The mill was dramatically enlarged during the summer of 1970, at which time the front of the old watermill became lost to sight as it was encompassed by a new large cladded structure. A modern pneumatic roller flour mill was then installed by the company Henry Simon, one of the leading milling engineers in the UK. By 1972 Duffields, having enlarged and modernised the mill, were taking in 100 tons of cereals a week and storing 225 tons of flour for biscuit making. Duffields chose

to concentrate their business on one site for the purpose of efficiency

and ease of communications - Saxlingham Thorpe mill is right beside the

Norwich - Ipswich road. |

|

2nd September 2007 |

|

Duffields' Milling History

|

|

1891-1892: W.I. Duffield started milling at the Black

Tower Mill, Mattishall, making stone ground flour. The mill developed

up to 20h.p. 1910: Saxlingham Mill was acquired 1919: Tharston Mill was acquired; Tasburgh and Saxlingham Mills were relinquished, but not for long 1924: William C. Duffield took over the mill at Buxton, remodelling it into a 2½ sacks per hour roller mill 1928: Saxlingham Mill was reacquired 1936: W.L. Duffield & Sons Ltd. was formed 1940: Animal feedstuff compound was first produced at Saxlingham 1950: Duffields acquired the tenancy of Hautbois Hall Farms (176 acres) 1951: Buxton flour mill was remodelled and capacity doubled 1952: Tharston flour mill was remodelled and capacity doubled 1953: Lamas Rectory and and 46 acres of glebeland adjacent to the farm were purchased 1960: The warehouse at Buxton was built 1962: The Duffield Group was formed with Duffield Mills Ltd. as the holding company 1963: A further 123 acres of land adjacent to the farm were purchased 1964: Buxton flour mill capacity was again doubled to ten sacks per hour 1965: The feed capacity at Saxlingham was doubled 1970: Modernisation at Saxlingham, doubling capacity

for flour production despite the closure of Tharston

and Buxton Mills. The group today employs a

staff of 109. |

The mill suffered £10,000 worth of flood damage in 1968 but survived. In 1972 the wheel was removed and the site was greatly enlarged. The new buildings that were erected almost completely enclosed the original structure. Until that time the waterwheel had still been used on occasions and was cleaned monthly. The last time the spur wheel was recogged, synthetic wood was used. The gable end of the old brick watermill building could still be seen from the road in 2005. |

|

In 1955, having left School and moved to Newton Flotman from Brooke, I worked for Duffield's at their Saxlingham Thorpe Mill, my job was to repair Sacks on the Sack floor. Some of them were repaired by having Patches sown on to them, this was the job of two Ladies, one of them, a young woman called Rita, and the other a Mrs Gailer. I repaired them by Gluing Patches on the inside with a EVOstick type substance. Another of my jobs was to clean out Flour Bags, which was done under cover in the Yard, by using a Suction Machine, the idea was to throw the neck of the Sack over the mouth of the Suction Pipe and the Sack would be sucked inside out. The Sacks were lined with Paper, therefore the suction was very strong, and on cold winter mornings, and your hands were numb if you didn't keep a tight grip on the Sack it would be swallowed up the Pipe to the Mesh Guard at the top, you then had to stop the Machine to allow it to fall back down again under it's own weight, you could often lose Fingernails if you were not careful doing this work. I left there to join the Royal Navy, (I was 16 and a half,) before I was called up for National Service. I also recall that at that time several of the Lorries were Ex-Army, named Crossleys. |

|

...all the machinery has to be destroyed. It's not allowed to be sold to another mill so they can increase their production. And the Four Milling Association would pay so much ... You couldn't sell off your machinery. That all had to go for scrap. In fact it even happened a few years ago with Duffield's Mill at Saxlingham. They decided to cease flour production and go completely onto animal feeds and all their machinery had to be scrapped just the same. |

|

I was employed by Duffields as project manager for the 1970 remodel and then mill manager until I took a new post in South Africa in 1973. |

My maternal 4xgreat grandfather was John Spratt the miller at Mulbarton, Shotesham_postmill, Shotesham watermill and Saxlingham Thorpe postmill and watermill. |

|

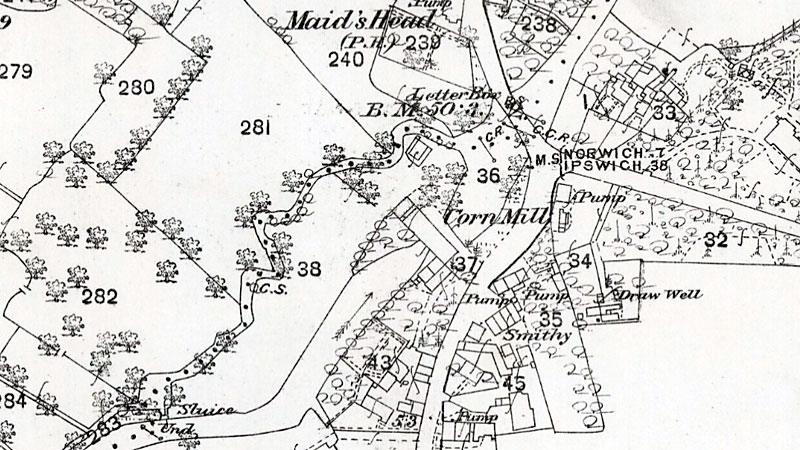

O. S. Map 1882 |

The dotted parish boundary line can be seen running along the original river course, latterly being used as the mill bypass. The river section now leading to the mill was dug in order to accommodate the mill and provide a sufficient head of water. |

|

O.S. Map 2005 Image reproduced under licence from Ordnance Survey |

|

Saxlingham

poll book 1768: George Watson 1828: Plan of late George Watson's estate drawn

White's 1843: Edward Reynolds White's 1845: Lawrence & Horatio Candler, corn millers

1928: Duffields bought the mill back Kelly's 1929: W. L. Duffield, miller, Saxlingham Thorpe roller mills; & at Tharston

1965: Animal feed production capacity doubled September 1968: Flooding at the mill caused damage of approximately £10,000 1970: Mill modernised and enlarged in £150,000 development 22nd May 1970: Due to expansion at Saxlingham, Duffields announced closure of Buxton and Tharston mills September 1970: Two electrically driven millstones still in use to grind wholemeal flour for biscuit manufacturing 1st March 1991: Duffields announce flour milling to cease after 101 years May 2011: Tony Duffield died aged 83 at Lammas |

If you have any memories, anecdotes or photos please let us know and we may be able to use them to update the site. By all means telephone 07836 675369 or

|

| Nat Grid Ref TM21209787 | Copyright © Jonathan Neville 2004 |