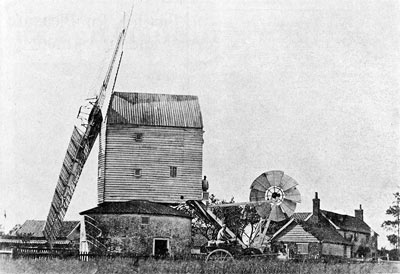

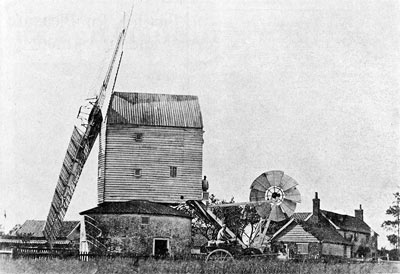

Garboldisham postmill |

|

c.1890 |

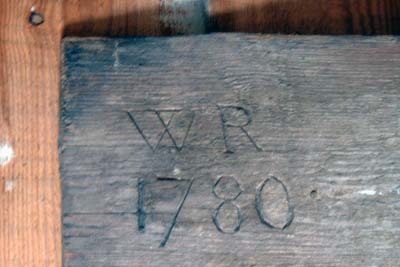

Garboldisham post mill was probably erected in the late 1700s and a piece of the original woodwork bears the inscription WR 1780. It is known that there were millers in the village in the 1500s and later in 1739, one Ishmael Pizzey bequeathed his windmill to his wife Penelope. |

The mill was modernised c.1830, when the original common sails were exchanged for 4 double shutttered patent sails, each with 8 bays of 6 shutters that were struck by rack and pinion. The 8 bladed fantail was mounted on a carriage attached to the stairway. The mill then had 2 pairs of underdriven French burr stones in the head of the buck. The brick roundhouse was 1½ storeys high, the upper window was horizontally barred and its roof was plastered. There was a single door and the walls were tarred to a height of 5 feet. The buck was painted white and after 1906 was roofed with iron sheeting. |

|

c.1890 |

In 1864 the sails were driving 2 pairs of 4ft 4ins French burr stones but in later years one pair of 4ft 4ins French burr stones and a pair of Peak stones were being used along with a flour machine and jumper. |

The millpost was 32 ins square at its base and 25 ins square at the top.. The sails were struck by rack & pinion, with the chain wheel half in and half out of the buck. The 8ft 6ins wooden brakewheel had a clasp arm with horns cast on a shaft instead of the square section and was controlled by an iron brake. Drive to the stones was via an iron wallower, spur wheel and mortice nuts. The mill's tail section incorporating the stairs, fantail and trolley at around 22 feet in length is the longest recorded in Norfolk. |

|

Date and initials carving |

Carved into the plaster in the roundhouse |

|

I |

R. Lon? Nov 1797 |

| Near the right of the door W B 1903 On the outside of the roundhouse, carved on the est pier, 5 feet from the ground I T (James Turner?) Lower down and 3 ft to the right I H |

|

... and also of all that my windmill in Garboldisham aforesaid ... to his wife Penelope Will of Ishmael Pizzey, miller of Garboldisham - 1739 |

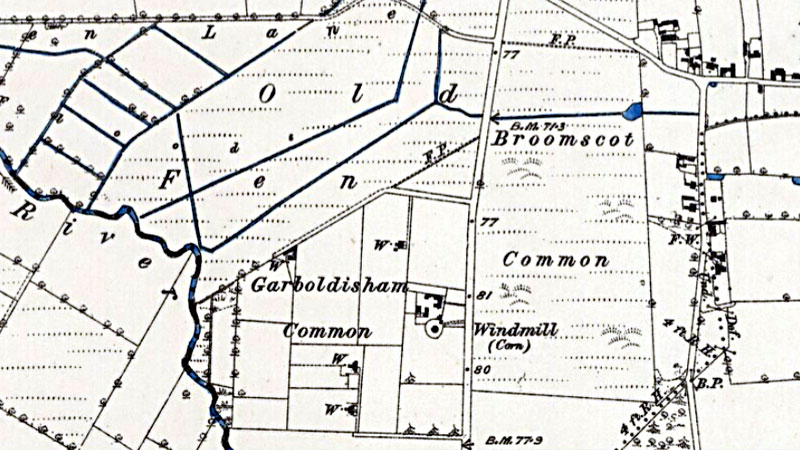

Around 1788 James Turner built a smockmill to the southwest of the postmill and in 1802 apparently sold both mills to John Button. In 1820 a towermill was built nearby, allegedly to the north of the postmill, although again it is noted that the 1888-91 O.S. map shows two mills to the southwest. The property was part of an estate owned by the Molyneux-Montgomery family for some 200 years before finally being sold off in 1944. |

RELEASE OF RIGHT |

Garboldisham POST MILL axletrees put up July 7th 1827. Patent sails put up on Garboldisham POST MILL March 1831. Diary of Thomas King of Thelnetham 1804 - 1838 |

In his diary, Thomas King of Thelnetham noted that on 7th July 1827 he put up an axletree. Later he replaced the original wooden windshaft with a cast iron windshaft and then replaced the common sails with patent sails in March 1831. Most of the machinery was replaced in cast iron and a fantial was added to allow for self winding. |

Extracted from the 1828 |

This is the last will and testament of me John BUTTON of Garboldisham, in the County of Norfolk, miller and I revoke all former wills……… I appoint my dear wife Mary Button and my uncle James Button of Thelnetham in Suffolk, Merchant to be executrix and executor. Gives to Mary all her paraphanalia, all household goods, furniture, beddings, beds, table and other linens, plate, china, stoves, fundues ?, five …….. all other household furniture in my dwelling house or in any other dwelling he resides in… And all such fixtures and effects as shall belong to me and be in and about or belonging to the mills, situate in Garboldisham aforesaid now in the several occupation of myself and John PEARL to and for her own absolute use and benefit independently of any debts which shall be owing by me at my decease (or demise?). And I authorize, empower and request them, my said dear wife and my said uncle James Button as soon after my decease as they or the survivor of them conveniently can be to collect and get in all debts which at my decease shall be due and owing to me. And to sell, and dispose of all my houses, cotts (cottages?), and other implements which shall then be used by me in my trade or business of a miller and all other my live and dead stock, cattle, chattels, and effects of any descriptions whatsoever, which shall then be used in or belonging to my trade or business as a miller (but not belonging to my farm), either by public or private auction or private contract…. And I give to my dear wife Mary Button, for her own personal use and benefit -- And whereas under and by virtue of the last Will and Testament of my late father John Button, power is given to me when in possession of the estates therein devised to me for my life and settle any part thereof upon or in trust for the benefit of any woman I shall marry during her life not exceeding a moiety thereof. And whereas I am as heir to my said late Father, entitled in my own right to certain Freehold and Copyhold Estates situate at Diss Haywood in the said County of Norfolk. Now therefore I the said John Button, the testator by virtue of the pursuance of the Power and Authority given to me in and by the said last Will and Testament of my said late father as well in my own right hereby give and devise unto her my dear wife Mary Button, and her assigns for and during the term of her natural life - All the real Estate situate in Wattisfield in Suffolk and Diss or Diss Haywood in the County of Norfolk which were respectively purchased by him my said Father as well as the Freehold and the Copyhold parts thereof with their respective rights, members, Priviledges and app…………. to hold the same etc……………..The will was written on 4th August 1827 and proved in the Archdeaconry of Norfolk Court by executrix Mary Button on 8th March, 1828, with power reserved for James Button to act………… (whenever?) Personals were under £2,000.00. |

|

|

c.1906 |

c.1908 |

Capital Estate & Corn Mills at GARBOLDISHAM in Norfolk To be Sold by Auction by Mr. H. Calver on Thursday 21 November 1839 at 3 o’c at the Fox Inn, Garboldisham. The Estate consists of a comfortable Messuage recently put into a thorough state of repair, Yards & Garden, Granary for 1000 coombs, Waggon Lodges, Stable, Gig house, Piggeries, Carpenter’s shops & other Buildings, a Post Windmill with roundhouse capable of containing 50 sacks of flour & chamber for 300 coombs, Patent Sails, Winding Tackle, Flour Machine & Jumper, two pairs of French Stones, 4 ft. 4 ins. Iron rightup Shaft, Wallower & Spur wheel, Iron Stone Nuts, Iron Bridge Trees, Iron Racks & all Running & Going Gears in complete repair. A Brick Tower Windmill four stories high in an enclosed yard near the above driving two pairs of French Stones 4 ft. 7 ins. & 4 ft. 4 ins., Flour Mill, Winding tackle & all Going Gears complete. The property is well situate in a populous neighbourhood about 15 miles from Bury, 7 miles from Diss & 4 from East Harling, all good corn Markets & an excellent Trade is now carried on. Apply to Messrs. Bignold, Fulley & Mawe, Solrs. Norwich, Mr. Daniel Calver, Solr. Kenninghall or the Auctioneer, Diss. Norfolk Chronicle - 2nd, 9th & 16th November 1839 |

GARBOLDISHAM |

To Millers. An excellent Situation for Trade at Garboldisham To be Sold by Private Contract or Let with Immediate Possession The Premises late in the occupation of Mr. Robert Button deceased comprising a comfortable Messuage recently put into a thorough state of repair, yards and gardens, granary for 1,000 coombs, waggon lodges, stables, gig house, piggeries, carpenter's shop and other buildings. A POST WINDMILL with Roundhouse capable of containing 50 sacks of flour and chamber for 300 coombs, patent sails, winding tackle, flour machine and jumper, two pairs of French stones, 4ft . 4 ins., iron rightup shaft, wallower, and spur wheel, iron stone nuts, iron bridge trees, iron racks, and going gears in complete repair. A Brick TOWER MILL, four stories high in an enclosed yard near the above driving two pairs of French Stones 4ft. 7ins. and 4ft. 4ins., flour mill, winding tackle, and all going gears complete. The Property is well situated in a populous neighbourhood about 15 miles from Bury, 7 from Diss and 4 from East Harling, all good corn markets and an excellent trade is now carried on. A Purchaser may be accommodated with a considerable portion of the Purchase Money at a modest rate of interest. Apply to Mr. Calver, Solicitor, Kenninghall, near East Harling, Norfolk, Norfolk Chronicle - 29th February, 7th & 14th March 1840 |

FIRE |

On Sunday morning, about 5 o'clock, the tower_windmill on Garboldisham Common, Norfolk, in the occupation of Mr J. G. Button, was discovered to be on fire, and although prompt assistance was rendered, nothing but the brickwork remains. We are happy to state that the greater part of the stock in trade was saved and the mill was insured. |

|

Tithe map 1842 - as redrawn by Harry Apling |

Tithe Award 1842 |

||||

No. 333 |

Mill & yard |

Pasture |

0a. 0r. 9p. (Tower mill) |

|

Land owner: Crisp Molineux Montgomerie |

|||

No. 43 |

Allotment |

3a. 3r. 21p. |

---- |

|

|

c.1920 |

c.1930 |

Four space 21 ft. breast to tail, 9 ft.9 ins. wide inside framing 8 ins. deep. |

c.1862 William Alfred Lawrence took over the running of the mill. He had come from East Harling where his father William and his uncle James ran East Harling towermill. |

TO MILLERS |

Messrs. BUTCHER are favoured with instruction to Sell by Auction at the King's Head Inn, Diss on Friday 2nd September 1864 at 4 for 5 o'clock the following DESIRABLE PROPERTIES in 2 lots, viz: |

|

5th July 1937 |

| At the age of 36, William Lawrence died from gangrenous frostbite on Christmas Morning of 1871, leaving his wife Emma to carry on the business. In 1872, the following year, she took on the 21 year old John Ellis Nunn from Dickleburgh to manage the mill and the farm, which turned out to be an astute move. |

1879, August 3rd, on Sunday morning happened a great storm that done so much damage about and took the sail of Mrs Lawrence's Mill. |

Great storm 3rd August. |

A great storm indeed struck the neighbourhood all around on that fateful day, and at Garboldisham two sails were torn off the windmill and hurled two hundred yards by the fury of the wind. |

When the damage was repaired by local millwright Alfonso Vincent, John Nunn had the mill lengthened by three feet to accommodate a flour mill to produce white flour. This necessitated the removal of the platform (or porch) at the top of the steps. In order to provide additional power, it would appear the two replacement sails were made 18" wider. At the same time, a steam engine to drive an additional pair of stones was installed in a nearby shed and drove a pair of stones mounted on a hurst frame within the roundhouse. |

|

|

c.1952 |

East Anglian magazine cover painting by Albert Ribbans 1959 |

|

1969 |

|

|

1st September 1970 |

1971 |

In June 1892 John Nunn married Jane Rebecca Barrett, youngest daughter of Emma Lawrence and soon left the employ of his mother in law and moved into Grange Farm where he successfully ran his own business. John Nunn eventually died in 1921 at the age of 70. |

After John Nunn moved to Grange Farm, Mrs. Lawrence's son, Frederick Barrett helped run the mill until a new manager was appointed. John Tuck then became manager and remained in service until Mrs. Lawrence retired in 1902. |

After Emma Lawrence retired the mill lease was taken on by the Pattinson Brothers who were running East_Harling_towermill. |

Charles W. Herring worked at the mill either before 1896 or after 1904 and during those years he was working at Moulton St. Michael postmill. |

In 1906 one of the sails was blown off in a storm. The opposite sail was then also removed and the mill continued to work with two sails. By this time, trade was running down and William Bennett, Mr. Pattinson's miller from East_Harling would drive over in a horse and cart to run the mill whenever there was sufficient work. Unfortunately William Bennett died suddenly in 1914 and the mill fell into disuse, with the business finally closing down on expiry of the lease in 1917. |

|

William Bennett c.1910 |

|

|

The mill supported on props October 1972 |

|

|

21st May 1973 |

When the Molyneux-Montgomery family sold the estate in 1944, Stephen Brock was still living in the Mill House and his son then bought farm and mill complex from the new estate owners. The mill became derelict over the years and was on the point of collapse, when in the spring of 1972, it was bought for £250 by George Colman of Ixworth, Suffolk. |

| Grant towards cost of restoration of £3050 from Department of the Environment. Eastern Daily Press - 15th September 1973 |

Electrically driven mill set up in roundhouse to grind wheat for sale. |

George Colman's son Adrian, then set about restoring the mill with professional help where necessary from millwright Philip Barrett-Lennard. A new Mill house was built to the south of the mill in 1977 as the original Mill House was not sold with the mill. |

|

|

September 1976 |

|

A History of Garboldisham Postmill Garboldisham windmill stands on high ground on Garboldisham Common, off the Hopton road, some way outside the village, and only a few hundred yards inside the county boundary. Originally two others stood in adjacent fields on either side, and another at Smallworth in the same parish. The latter was a small, rather Heath-Robinson affair, built by one Alfonso Neville Vincent, a millwright and stone-dresser from the nearby Thelnetham windmill. It was his own design, with four canvas-spread sails, the drive being coupled to a 'Woods' plate-mill, of which the output was very small. 'Ponto', as he was known, was a local character who went about stone-dressing in a governess cart pulled by a donkey, his wife taking him to work in the morning and bringing him back at night. Of the other three windmills, a document of 1811 reveals that two were built by James Turner, a farmer of nearby Blo' Norton: first the present post-mill, and then a smock-mill, the latter in 1788. The earliest date so far found inside the present mill is 1778 on a board, but erection of the structure may have preceded this by a few years, the roundhouse possibly being added about 1787 - in which case the original brick piers must have been replaced, as the roundhouse wall and piers form an integral part. In 1802 both mills were sold to one John Button for £795, and in 1820, according to a local diary, Garboldisham tower-mill was built close by. The Button family seem to have carried out extensive modernisation around 1830. According to the diary of a local miller, Thomas King of Thelnetham, 'Garboldisham Post Mill Axle-tree put up July 7th 1827' and 'Patent Sails put on Garboldisham Post Mill in March 1831'. The present cast-iron machinery and fantail were probably added at the same time. There is clear evidence for a tail-pole, and it is quite likely that the millstones were head-and-tail layout, because the left-hand pair seems very old and rather large so that it was found necessary to hack a section to a depth of 2" off the inner edges of both side-girts to achieve the present layout. The next decade or so is slightly confusing. All three mills are shown on the First-Edition O.S. Map of 1837. In 1839 the post-mill and tower-mill were put up for auction. However, the Button family were still running the mills after that date; so, were they tenants, the freehold being sold, or were the mills withdrawn from auction? According to the Suffolk Chronicle of 22 August 1840 there was a fire at the towermill and nothing but the brickwork then remained. And yet, on the 1842 parish tithe-map, the two remaining mills appear to be the post-mill and tower-mill - perhaps it is the smock-mill which was burnt down as this had gone by about that date. (A smock-mill stands on a brick plinth.) The fate of the tower-mill is not known, although it is thought to have lasted until 1860; only the present post-mill is shown on later maps. The Button family continued to work the post-mill until about 1864, when William Button went to mill in the Diss area and it was taken over by a young man from East Harling, William Alfred Lawrence, whose father William and uncle James had the tower mill there. The family seemed prone to disaster. In a short space of time they lost five of their eight children, three of bronchitis in infancy, two were stillborn; William Alfred lost a horse which suddenly dropped dead between the shafts of his waggon; his wife, Emma, was knocked down by the sails of the windmill, receiving severe concussion; and later, while she was alone and unaided, some unknown person or persons tried to force an entry into the Mill House. On Christmas morning 1871, William Alfred, aged only thirty-six, died of gangrene resulting from frost-bite caught while he attended to the sails in bad weather. His poor wife was left to run the business and bring up a young family, in those days no easy task. She was, however, a woman of great character, for which she is justly revered by her descendants. Obviously she could not run the business alone, and in 1872 a young man of 21, John Ellis Nunn, came from Dickleburgh to manage both farm and mill, which had always been run together. He was of humble origins and means, but the business very soon began to prosper under his very able direction. Seven years later, however, '1879, August 3rd, on Sunday morning happened a great storm that done so much damage about and took the sail of Mrs Lawrence's Mill'. This entry in villager George Doe's diary is confirmed by the Diss Express of the following Friday: 'A great storm indeed struck the neighbourhood all around on that fateful day, and at Garboldisham two sails were torn off the windmill and hurled two hundred yards by the fury of the wind.' This was quite a set-back for Mrs Lawrence, but John Nunn seized the opportunity for certain necessary alterations to be made, and repairs were soon put in hand by Alfonso Vincent with the local estate carpenter. According to Stanley Nunn, eldest son of John Ellis Nunn, 'The width of the replacement sails was increased from 4'6" to 6'0" (on the driving side) which enabled two pairs of millstones to be utilised, and a small flour mill with cloths (dressing machine) which enabled a nearly white flour to be manufactured in place of brown flour or wholemeal'. For this purpose the mill was completely extended some three feet at the rear, where there had previously been a platform at the top: of the steps, and possibly a Norfolk-style porch. Owing to the uncertainty of the wind, a steam engine and boiler were also added in a nearby outhouse that drove a pair of stones within the roundhouse via a slack belt. During the succeeding years trade remained brisk, and both mill and farm flourished. John Nunn gained a high reputation in the neighbourhood, and it came as no surprise when, in June 1892, he married Mrs Lawrence's younger daughter, Jane Rebecca Barrett. In the meantime her elder daughter, Emma Mary, became a school teacher and married William Balls, the headmaster of Garboldisham school. John Nunn and his new wife soon moved up the road to Grange Farm, where he continued to trade very successfully, mainly in hay. A self-made man of much local property and in high esteem, he died in 1921 at the age of seventy. After John Nunn moved to Grange Farm, Mrs Lawrence's son, Frederick Barrett, assisted her with the business. He later married Helen Morley, daughter of the owner of the local post office, and moved away to London, where he spent the rest of his life. A new manager was then engaged, Mr John Tuck, grandfather of the founder of the well-known modern millers. Tucks of Burston. A distinguished-looking man with a long white beard, he was rather saucily known to the Harling boys as 'snout and whiskers'!" He had previously been in business on his own account at Little Snoring and Hindringham windmills, near Fakenham, and was an accomplished organist and counter-tenor. Trade, unfortunately, had now begun to decline at the mill, due to the construction of huge modern mills, and to the installation by local farmers of an oil engine and small plate-mills. On Emma Lawrence's retirement from business in 1902, the property was taken over on lease by the Pattinson brothers of East_Harling_windmill, who had succeeded the Lawrences there too. Mrs Lawrence remained, however, in one half of the Mill House, while the new tenants occupied the other half. Shortly after this, a local man, Stephen Brock, came to assist with the running of the mill, carting, etc. Two years later, in 1906, another accident occurred. Wet rot had previously begun to appear in one of the sail stocks, and one windy, stormy Sunday night, while the mill was running, one of the sails was blown off and smashed on the ground. It was severely damaged, and the opposite number was removed by Mr Ling, the estate carpenter, to restore the balance, and was taken to the local estate yard on a four-wheel drug, where it was eventually cut up and reused for other purposes. The mill continued to work with two sails, but with war restrictions the grinding trade dwindled to almost nothing, and Mr Pattinson employed a miller, William Bennett, who would travel over from East Harling with a high cart and white horse whenever necessary. On the decease of Mr Pattinson's father, and the sudden death of his miller in 1914, the mill became virtually disused, and when the lease expired in 1917, the business closed down, and Mr Pattinson's belongings were removed. Five years later Emma Lawrence died, and the work of the mill was done. The Old Mill Farm had always stood on the Garboldisham Hall Estate, belonging for two hundred years to the family of Molyneux-Montgomery. The last owner, Major Montgomery, died in action during the Great War, but his daughter was adamant that the mill should stand until it fell. The property was accordingly let to Stephen Brock, and for many years the windmill stood decaying until it gradually became derelict. In 1944 the estate was sold for family reasons by Miss Montgomery, at which time Mr Brock was still the tenant at the Mill House. His son later bought the premises of farm, mill, house, barn, stables, etc., from the new owner on behalf of his father. After several attempts at vandalism, which were partly successful, the mill was once again left in peace. The passing of the years, however, left their mark, and when Garboldisham post-mill was finally sold to a sympathetic young owner in 1972, it was sorely in need of urgent repair. Fortunately this has been carefully and speedily undertaken, and there is no doubt that this lovely old mill will continue to grace the skyline over Garboldisham village for many years to come. AGKNOWLEDGEMENTS I should like to acknowledge with thanks the valuable assistance afforded me by Mr and Mrs S. Flatman, Mr Stephen Brock, and several other local villagers, together with Mr J. Pattinson of East Harling and Mr Dennis Lawrence of London, without whose help this history could never have been compiled; and Mr Peter Dolman for sending me the extracts from the Bury & Norwich Post and the Suffolk Chronicle. Phillip Unwin - Brome, Suffolk, 1973 |

Owner of mill: Major H. A. Dewing |

|

|

Roundhouse under repair in 1973 with new trestles above |

Roundhouse interior c.1980 |

Mill restoration work 1972 - 1997 |

Autumn 1972 1992-1997 |

|

1989 |

|

|

Spring 1992 |

5th July 1995 |

|

|

Adrian Colman repainting June 2001 |

Sails canister 13th September 2005 |

|

|

13th September 2005 |

Fantail 13th September 2005 |

|

Stairway & fantail with new mill house in background 13th September 2005 |

|

|

Top of post and crown tree 13th September 2005 |

Brakewheel and sackhoist 13th September 2005 |

|

|

Trestle and roundhouse roof 13th September 2005 |

Stone floor with pair of restored stones 13th September 2005 |

| My name is Amy Brock, I have just been looking at the Garboldisham mill. My great granfather Stephen Brock with his wife May lived at the mill. My grandad James Brock, Stephen's son brought the mill, I see that info is still on there if you look in the brick work I think on the house it is ingraved Amy Brock that is James daughter she did it. I was named after her by the way. I do have a pic of my great granfather at the mill it was one the newpaper had took. Amy Brock, grandaughter of ex owner James Brock - 2nd September 2008 |

|

14th June 2009 |

|

|

22nd March 2011 |

|

History of the Buck Roof & 2015 Repairs |

The original roof, dating from the 1700’s, is still intact – it is the roof covering which has changed. |

|

|

Prior to roof repairs - February 2015 |

Roof repairs in progress - 2015 |

|

|

Roof repairs in progress - 2015 |

Roof repairs in progress - 2015 |

|

|

Buck roof repair completed - 2015 |

Buck and roundhouse repairs completed - 2015 |

Mill Painting |

From the beginning of the restoration of Garboldisham windmill, in the early 1970’s, the new weather boarding for the buck was painted with White Lead Paint. When repainting was necessary I continued to use WLP and would have used it again this year had it been available. |

|

|

Adrian Colman painting the mill - 1st May 2021 |

Mill painting complete - 11th May 2021 |

Mill Maintenance |

This morning I completed the task of covering the roundhouse roof with a double staggered layer of 6mm thick plywood which will form the base for aluminium sheets. |

|

|

Plywood being attached to the roundhouse roof - 9th November 2021 |

Roundhouse roof with full covering of plywood - 19th November 2021 |

Mill Maintenance |

Millwright Bill Griffiths has almost finished putting aluminium sheeting over the plywood base which l fitted in the autumn of 2021. |

|

|

Roundhouse roof with aluminium covering being fitted over the plywood - 25th April 2023 |

|

|

|

Roundhouse roof with aluminium covering - 25th April 2023 |

25th April 2023 |

As a young child l was fascinated by windmills, water mills and castles. A distant relative was one of the last commercial millwright’s in Norfolk. Thompson of Hardwick - alas at the end of his career he was more involved in the dismantling than the repairing, as mills went out of use. |

|

O. S. Map 1883 Courtesy of NLS map images |

Index of Wills 1580: Richard Carman, miller 1828: John Button made his will

Tithe Award 1842: Mrs. Mary Button (owner of postmill and towermill) John Button, occupier

White's 1854: William Button, corn miller c.1862: William Button left the postmill to run a mill in the Diss area c.1862: William Alfred Lawrence, tenant miller from East Harling Friday 2nd September 1864: Mill for sale by auction White's 1864: William Lawrence, corn miller 1864: William Alfred Lawrence, miller 25th December 1871: William Alfred Lawrence died from gangrenous frostbite aged 36 1872: Emma Lawrence (widow) owner; John Ellis Nunn (21) from Dickleburgh farm and mill manager Sunday 3rd August 1879: Gale tore off two sails 1879: Tail of buck extended to accommodate flour sifting machine and wider replacement sails installed by Alfonso Vincent Kelly's 1879: Emma Lawrence (Mrs.), miller White's 1883: Mrs. Emma Laurence, miller 1886: Mrs. Emma Lawrence, miller 1886: Horace Edward Hutson, journeyman mill left the mill to go to Wells, having served his apprenticeship O.S. map 1888-91: Postmill and 2 mills to southwest Kelly's 1892: Emma Lawrence (Mrs.), miller (wind & steam) & farmer June 1892: John Nunn married Mrs Emma Lawrence's daughter Jane Rebecca Barrett c.1892: Mrs. Emma Lawrence's son Frederick Barrett took over running the mill before moving to London c.1895: John Tuck employed by Mrs Emma Lawrence to run the mill. Previously at Lt Snoring & Hindringham Kelly's 1896: Emma Lawrence (Mrs.), miller (wind & steam) & farmer Kelly's 1900: Emma Lawrence (Mrs.), miller (wind & steam) & farmer 1902: Emma Lawrence retired 1902: Pattinson Brothers from East Harling leased the mill from Emma Lawrence Kelly's 1904: Christopher George Pattinson, miller (wind & steam) & farmer c.1905: Stephen Brock, mill assistant and carter 1906: Sail blown off the mill in a gale one Sunday night. Opposite sail then removed to balance the mill Kelly's 1908: Christopher George Pattinson, miller (wind & steam) & farmer Kelly's 1912: Christopher George Pattinson, miller (wind & steam) & farmer 1913: Christopher George Pattinson bought East Harling towermill 1914: Mr Pattinson's miller suddenly died and mill virtually ceased working Kelly's 1916: Christopher George Pattinson, miller (wind & steam) & farmer 1917: Pattinson's lease expired and mill finally closed down when last employee called up for military service 1922: Mrs Emma Lawrence died 1922: Mill, Mill House and property let to Stephen Brock before being bought on his behalf by his son 1926: Mill derelict 1944: Estate sold by Miss Mongomery of the Molyneux-Montgomery family c.1945: Stephen Brock's son bought Mill, Mill House and the farm 1949: Mill derelict 1959: Mill derelict 29th March 1972: Mill bought by George Colman of Ixworth, Suffolk for £250 1972: Mill house owned by ? Poerpower and let to Americans 1972: Adrian Colman began restoration of the mill as detailed above c.1975: Electric mill installed within the roundhouse to assist with onsite sales 2005: Some flour milled on the premises and a large selection of cereal products on sale 2005: Mill open for viewing by appointment only 2021: Mill repainted and in good condition |

If you have any memories, anecdotes or photos please let us know and we may be able to use them to update the site. By all means telephone 07836 675369 or

|

| Nat Grid Ref TM 00278047 | Copyright © Jonathan Neville 2005 |