|

|

1901

|

|

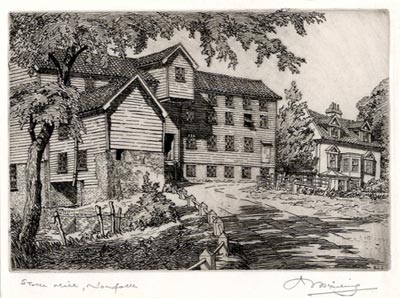

Stoke Holy Cross

Mill

River Tas |

|

|

1901

|

|

Stoke Holy

Cross watermill was built of weatherboard over a brick base with a pantiled roof. The water

had a fall of 12 feet to power the two breast shot wheels and unusually

a wooden chute served to carry the water away from the foundations. When

milling corn, the wheels were driving seven pairs of stones, which made

the mill one of the largest in the county. This was one of only a few

mills in Norfolk to have the stones driven from the spur wheel set above

them - five stones from one spur wheel. |

|

Stoke Holy Cross watermill is on a very old site, possibly dating back to Roman times and is quite close to the Roman fort at Caistor_St._Edmund. It was mentioned in 1482. A mill on this site was burnt down in 1744 and rebuilt in 1747. |

|

In 1746 Abraham Caught jnr., paper maker, son of Abraham Caught snr., deceased and William Largent, paper maker and wife Mary, daughter of Abraham Caught snr., deceased, conveyed the mill to James Denny. |

|

On Thursday died Mr. Denny, Proprietor of the paper mills at Stoke, near this city. |

|

in 1778 James Denny's exector Henry Cooke, gent., leased the mill for 21 years to Ralph Buck, the lease being assigned to George Watson, gent., in 1788 and to Thomas Skelton in 1794. |

|

|

|

c.1907

|

Mill working c.1910 |

|

Colman's label |

|

In 1814 Daniel Ames, gent., leased the mill for 21 years to Jeremiah Colman, flour merchant, who covenanted to leave the water wheel, pit wheel, French burr stones and boulting mill in situ at the end of his term. |

|

For many years the mill was worked in conjunction with the adjacent tower mill at that was built by Jeremiah Colman. The windmill drove four pairs of stones. |

|

Born 16 July 1777 |

||

JAMES | JEREMIAH JAMES | RUSSELL JAMES (1861 - 1946) |

EDWARD | FREDERICK | GORDON |

JEREMIAH etc. | JEREMIAH |

| Harry Apling - c.1982 | ||

|

JAMES COLMAN |

Born 18 November 1801 Son of ROBERT Taken into partnership by JEREMIAH at Stoke Holy Cross 15 February 1823 1st August 1826 married MARY BURLINGHAM at Old Buckenham. MARY, born at Great Ellingham 24 October 1805, daughter of JOHN & MARY BURLINGHAM of Old Buckenham. Children:- JEREMIAH JAMES COLMAN born 14 June 1830 MARY ESTHER COLMAN born 27 August 1838 JAMES COLMAN died 19 October 1854 aged 53 His wife MARY died 15 September 1898 aged 92 In about 1856 the firm of J. & J. COLMAN began to transfer their mustard business to Carrow Works, Norwich, the transfer being completed in 1860. 17 May 1862, JEREMIAH JAMES COLMAN, trading as J. & J. COLMAN bought Old_Buckenham_Mill and property from JOHN & GEORGE BURLINGHAM (MARY's brothers) and HARVEY & HUDSON, bankers Norwich, their mortgagees. |

|

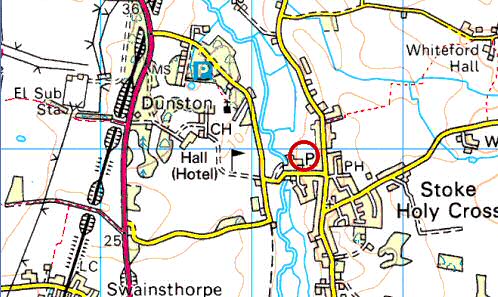

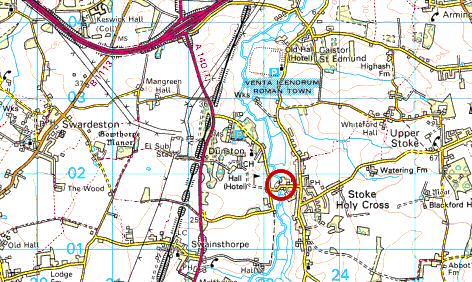

O.S. Map 2005 Circle marks the site of the towermill Image reproduced under licence from Ordnance Survey |

Deeds of Stoke Mill, described in 1766 as capital messuage with paper mill, barn, stable, drying houses, mill houses, shop, offices, etc., messuage called the Gatehouse with farm in Stoke and in 1825 as messuage and water mill with drying kiln, counting room, outhouses, water wheel etc., windmill lately built by Jeremiah Colman, two double cottages, and land cont. 22a. 2r. 35p. Settled in 1766 before marriage between James Denny, gent., and Sarah Dyball, spinster, with two messuages, land etc. in South Elmham St Margaret and Flixton, Suffolk, and 1767 conveyed to Henry Cook charged with payment of annuity to Henry Samuel Cooper, clerk. In 1791 Henry Cook conveyed to Thomas Cook and in 1795 Thomas and Henry Cook and their wives conveyed it in trust for Daniel Ames, with assignment of machinery inc. paper engine and presses. |

|

|

c.1920

|

|

In 1814 Daniel Ames, gent. leases for 21 years Stoke Holy Cross watermill to Jeremiah Colman, flour merchant. Colman covenanted to leave water wheel, pit wheel, French burr stones and boulting mill at the end of the term. |

|

|

|

May 1968

|

May

1973 |

|

The mill had 7 sets of stones instead of the usual 4, although it is possible that the second wheel was being used to drive at least two of them. Unusually, the spur wheel was situated above the stones and thus also provided the drive from above. This meant that the drive did not have to pass through the bedstone as was usual. The only other Norfolk mills found to share this arrangement so far are Hunworth, Snettisham, Thornage and Weybourne. |

|

|

|

c.1950

|

January

1963 |

|

After the death

of James Denny, Edward Ames became the owner and he closed the mill on

two occasions. The first was as the result of a child drowning in the

river, which seriously upset Mr. Ames. However, he reopened what was a

flour mill as a paper mill. Later, the visit of a revenue officer, to

assess the amount of tax to be paid, so angered Mr. Ames that once again

he closed the mill. |

|

|

May 1973

|

|

On 3rd April

1814, Jeremiah Colman of Pockthorpe_towermill, leased Stoke Holy Cross watermill as a going concern and paid £51

2s 0d to Edward Ames for his stock of mustard. |

|

JEREMIAH COLMAN |

|

|

|

Jeremiah Colman was originally a farmer and had also owned Bawburgh_Mill and a windmill outside Magdalen Gates. He had no son and adopted James who was the eldest of his brother Robert's 15 children. The present Colman family of Norwich are descendants from James. Jeremiah was a devout Baptist, kindly, honest and a good master. Under his ownership between 1814 and 1850 wages at the mill rose from 8/10½ to under £1. Boys of 8 or 9 worked 12 hour shifts with 2 breaks and earned 3d per hour. A working day was normally 6.00am to 6.00pm although sometimes a shift could go on until midnight. Many workers then faced a long walk home. The Colman family took a benevolent interest in their workforce by supplying schooling and contributing to the social life of its staff e.g. Christmas dinner in the granary and staff outings. The company was one of the first to offer a meals service for its workers - four pence bought hot meat, vegetable stew and a pint of coffee. Colman's also provided a clothing club and lodgings for working girls, followed by a lending library and a pension fund. In 1878 the company employed the first industrial nurse, Philippa Flowerday. |

Arthur Cole (1835-1902) was journeyman miller who travelled between many mills including Stoke Holy Cross. |

|

|

A working wheel c.1910

|

|

|

Side wheel site April 1977 |

Side wheel site 2nd June 2005 |

|

In 1830 the

company began to manufacture starch from wheat. In 1850 tins were introduced for the first time and soon took over from the casks. In 1851 the founder Jeremiah Colman died. Later on James' son J. J. Colman (photo below) took over sole charge to run the company. In 1853 White's Directory records that "An alarming fire broke out in a spacious room used for drying starch at Messrs. Colmans' premises, and but for its timely discovery, a far larger work of destruction would have taken place. The application of a quantity of chlorine liquor had a great effect in stopping the ravages of the fire but the building was considerably injured and twenty tons of starch seriously damaged. The estimated loss £1000." In 1862 the lease ended and by now the business was too large for Stoke Holy Cross Mill. Thus Colmans moved to the present site at Carrow. |

In October 1860, Thomas_Smithdale agreed to make some new machinery to William_Thorold's plans and specifications. |

|

Mr. Thorold, Dear Sir, Agreeable to your request I beg to say I am willing to make & fix at Stoke Mills one set of Stone Pans, with Wheels, Governors & connecting Shaft &c. &c. for do. Also hang one pair of Friction Wheels on Horizontal Shaft and Stone Spindle according to plan and Specification. The Work to be done in a Workmanlike Manner for the sum of fifty pounds. £50. -. -. I am, Dear Sir, Your Obt. Servt, Thos. Smithdale. |

|

To be Let. Possession at Michaelmas 1862 |

On 17th May 1862, J. & J. Colman bought Old Buckenham towermill from John & George Burlingham and their mortgagees Harvey & Hudson.. |

|

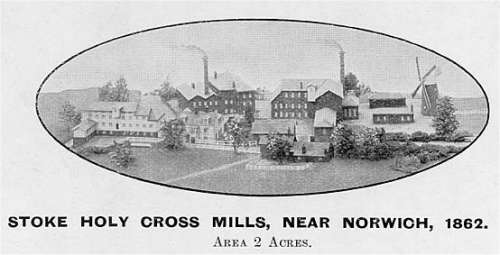

STOKE HOLY CROSS MILLS |

|

Mustard from the field to the table |

|

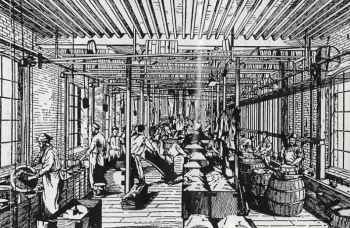

Mustard is made from the seeds of plants of the Brassica (cabbage) family which are grown mainly in the eastern counties of England. Two kinds are used - one yielding brown seed, the other white. At the factory they are milled separately but in exactly the same way. First the husk is broken on rollers to release the kernel. Next the husk and kernel are separated in a purifier using sieves and currents of air. The kernel then passes through further rollers which progressively reduce it to a fine powder. For ready mixed or prepared mustards other ingredients are added and the mixture packed into jars. In the days at Stoke and up to 1870 the mustard powder was produced by a kind of mechanical pestle and mortar called a 'stamper' and the resulting flour sifted out on 'frames' fed by hand. Jeremiah Colman was still personally sifting his own mustard flour after twenty years at Stoke Holy Cross. In the Bridewell Museum in Norwich one of these early 'stampers' once used in the commercial preparation of mustard can be seen. |

Mustard stampers |

|

As far back as 1878 the farmers of the Fen country who grew mustard crops would take samples of the seed in small home-made canvas bags to the company's agent who on three successive Saturdays in October held a market in Dawbarn's shop in Wisbech. The sample would be inspected, a price offered and a bargain struck. The crop would then be delivered to Colmans in sacks by rail. Today mustard is still grown by farmers on a contract basis. Specially selected seed is supplied to them together with advise on cultivation. After harvesting the entire crop is bought by Colmans. Much of the seed milled in Norwich is grown in the

eastern counties of England, and you may have seen the brilliant yellow

fields of flowering mustard towards the end of June. The seed is harvested

in August and delivered to Carrow by the growers. |

|

|

Mustard production in the 1890s

|

|

The one armed

packer mentioned above was reputed to be one Lazaris Horne who had lost

his arm fighting in a war in the USA. |

|

|

J.J. Colman M.P., D.L. 1830 - 1898

|

|

James Colman was in reality the son of Robert Colman but he was the adopted

by Robert's brother Jeremiah, the famous mustard company's founder. James Colman married Mary Burlingham, daughter of John Burlingham of Old Buckenham in 1826 and they had a son, Jeremiah James Colman, born on 14th June 1830. In 1856 he married Caroline, the daughter of William Cozens-Hardy of Letheringsett Hall. |

|

|

The Colman dynasty |

|

MUSTARD - SEED OF A GREAT IDEA |

February 15th, 1823 , was a significant date for Norwich and Norfolk. It was the day when Jeremiah Colman took his nephew James into partnership. Thus began the J. & J. Colman business which was to have such a beneficial effect, not only on the life of city and county, but farther afield. |

|

LONG of Dunston

records: |

|

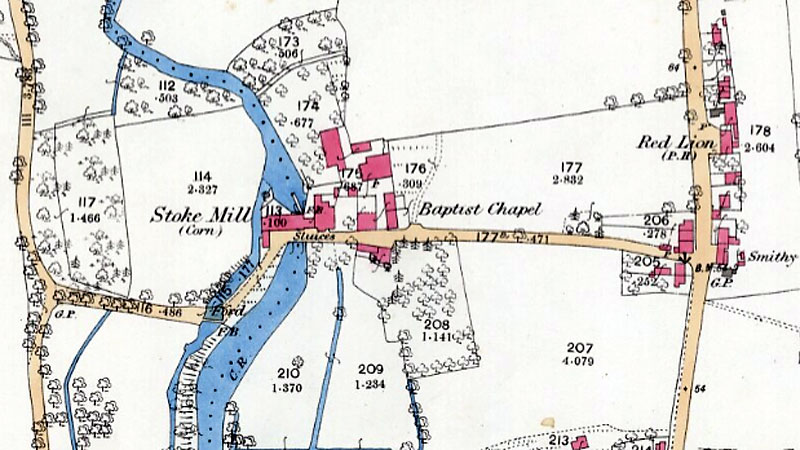

Tithe Award 1844 |

|

|

| No. 145: Part of Watermill, House, Yards etc. Pasture | 0a. 3r. 32p. |

4/- Vicar |

| No. 146: Mill Piece. Arable | 8a. 3r. 8p. | £1.1.7 Vicar £2.11.8 Apptr. |

| No. 147: Windmill Piece. Arable | 3a. 0r. 22p. | 8/4 Vicar 19/10 Apptr. |

| Shows tower mill with stage |

|

Tithe Award map 1844 - redrawn by Harry Apling |

|

Messrs. J. and J. Colman, Stoke. I beg to hand you a price for a pair of new feed rolls the same size as the pair now at work at your Mill at Stoke. The rolls to be bored and turned. Two ham'd iron gudgeons four inches diameter turned to fit bearings & rolls and well keyed into Do. To make a new cast iron frame with all new bell metal brasses fitted to the same and bored to fit the gudgeons, two cast iron spur wheels to rolls, one spur wheel and pinion to drive the same with feed rolls will amount to Fifty Five Pounds. |

|

£55.00.0.0

May 18th 1850 |

I remain. Your Obedt. & Hble. Servt. John S. Buttifant. |

|

J. and J. Colman have a large mustard, starch, seed-crushing, and corn mill here, which gives employment to a great number of hands. On November 24th, 1853, an alarming fire broke out in a spacious room used for drying starch, on Messrs. Colman's premises; and, but for its timely discovery, a far larger work of destruction would have taken place. The application of a quantity of chlorine liquor had a great effect in stopping the ravages of the fire; but the building was considerably injured and twenty tons of starch seriously damaged. The estimated loss was about £1,000. |

|

St. Ann's Iron Works, King St. Norwich, Mr. Samuel Colman, Dr Sir, August 11th 1858. I beg to say the Price of One Double Hydraulic Press 4ft. 8in. between Columns and Rams by 3ft. with 12in. Diameter casing distance 8in. with 4 wrought iron Columns to each Press 31/8in. Diameter for working Pressure of 400 Tons each, with one set of Gun Metal Double Pumps 2½in. x 1in. Dia. Rams with Double stoppers Complete for the Sum of Two Hundred and Eighty five Pounds. £285. =. =. I remain, Your Obedient Servant, Thos. Smithdale. |

|

St. Ann's Iron Works, King St, Norwich, Nov 22nd 1858. Mr. J. J. Colman, Dr Sir, Agreeable to your request I beg to hand you the Price for Three Single lift Hydraulic Presses 5 feet by 5 feet, with 9 inch Ram and 9 inch Lift with 6 Wrought iron Columns of 3 inches Diameter to each Press and one sett of Gun Metal Double Pumps 2½ inch and one inch Diameter Rams, with 3 setts of Gun Metal Double Stoppers and Stop valves complete for Working pressure of 100 Tons each, with connecting Pipes and Ram Leathers, the above to be fitted and finished in a Workman like manner as per Drawings and forwarded to Carrow Works for the Sum of Four Hundred and Fifty Pounds. £450. 0. 0. I remain, Your obedient Servant, Thos. Smithdale. |

|

Mr.

Thorold, Dear Sir, Agreeable to your request I beg to say I am willing to make & fix at Stoke Mills one set of Stone Pans, with Wheels, Governors & connecting Shaft &c. &c. for do. Also hang one pair of Friction Wheels on Horizontal Shaft and Stone Spindle according to plan and Specification. The Work to be done in a Workmanlike Manner for the sum of fifty pounds. £50. -. -. I am, Dear Sir, Your Obt. Servt, Thos. Smithdale. |

|

To be Let.

Possession at Michaelmas 1862 |

|

A Baptist Chapel was built here about 20 years ago by Messrs. J. & J. Colman, but it is now used as a kind of Chapel of ease, evening service being performed in it every Sunday by the vicar. |

|

Ink sketch by Henry James Starling c.1945 |

Elijah Eglington, who ran the mill in the 1880s was born on 19th January 1828 at Gt Witchingham. He married Elizabeth Flarty (orig. Flaherty) in the June quarter of 1849 at St Olave Southwark in London and they went on to have nine children. Most of their Norfolk family had to be baptised in private because of the laws

during the 17th, 18th and 19th centuries, which didn't favour Catholicism. |

Tobias William Pilch Beverley was known as William Beverley. He was born 1849 and married Harriet Henrietta Rackham in 1876. Harriet had died by 1901 and the census of that year recorded that Harriet's sister Emily was employed by William as housekeeper and was living in the household. In 1908 William Beverley married Emily Maria Rackham. William Beverley died in 1910. |

|

|

|

Tailrace April 1977

|

Tailrace 2nd June 2005 |

|

Tailrace 10th December 2007 |

|

In August 1998, Keith Fowler organised a reunion of Colman's Mustard employees. Keith was a former head rollsman at the Norwich millers R. J. Read before moved across the river to join Colman's Mustard. He then worked through from the bottom to become manager of the mustard department where he remained until he retired. |

|

|

Colman's workers reunion 21st August 1998

|

|

Back Row: Mark

Dyble, Paul Setchell, Mick Bradford, Mike Farrow, John Wilson, Billy Nichols,

Kevin Cooke, Tony Gotts, John Thurley, Mark Stone. |

|

|

Watercolour painting by Harry Peters dated 1976 |

|

|

|

April 1977

|

Old

Mill Restaurant April 1977 |

|

Over the years the riverbed was damaged and scoured by a series of floods. Most notable were those in 1849, 1912 and 1968. |

|

The wheel was removed in about 1952 and the remainder of the machinery was sold off in 1963. |

|

Watercolour by John Watson 1999 |

|

|

|

15th February 2003

|

Mill and mill house February 2003 |

|

|

Mill & Mill House 2nd April 2005 |

2nd September 2007 |

|

2nd June 2005 |

|

John Crome painted a floral decoration on the ceiling of one of the rooms in the mill house. |

|

Colman's owned several wherrries including the Hero, Hope, Lucy, Plane, Star of Hope Walberswick and William. |

|

William Frederick Brock was part of a Norfolk milling family and was born in the mill house at Sprowston. |

|

I thought you might be interested to know that the miller at Stoke Holy Cross in 1871 was Thomas Edward Wells, son of William Harrison Wells of Dilham and New_Mills. |

|

Original and 3 Bicentenary labels - 2014 |

|

On 5th January 2018, Unilever announced that Carrow Works will close and all mustard production will move to Burton on Trent in 2019. Mustard milling will continue at a new Norwich mill, allowing for the brand to retain the Norwich name. |

|

O. S. Map 1880 |

|

O.S. Map 2005 Image reproduced under licence from Ordnance Survey |

|

1700 - 1710:

Mr. Fitt, miller 1786: Robert

Buck (son)

Robson's 1839: J. & I. Colman, Oil & Mustard Mills

3rd December 1851: Jeremiah Colman died aged 74

19th October 1854: James Colman died leaving Jeremiah James Colman aged 24 as head of the company 1862: Colmans'

sell and leave the mill having moved to Carrow

White's 1864: Durrant & Co. manufacturers of patented food for pheasants and poultry

1875: Benjamin Larkin Cross was the manager Kelly's 1879: Elijah

Eglington, miller

December quarter 1883: Harriett Henrietts Beverley, wife of William Beverley, died aged 29

Kelly's 1892: William Beverley, miller (water) Kelly's 1896: William Beverley, miller (water)

Kelly's 1904: William Beverley, miller (water) Kelly's 1912:

Mrs. Emily Beverley, miller (water) Kelly's 1922:

Herbert R. Mutimer, miller (water)

Kelly's 1937: William Frederick Brock, miller & hay & corn merchant. T.N. Framingham Earl 33 1952: Waterwheels and gearing removed 1960: Mill owned by Mosses & Mitchell Ltd (Plastics) 1963: Machinery sold off 1970s: High

class restaurant opened by Adrian Asbury |

If you have any memories, anecdotes or photos please let us know and we may be able to use them to update the site. By all means telephone 07836 675369 or

|

| Nat Grid Ref TG23230185 | Copyright © Jonathan Neville 2004 |