|

|

February

1977

|

|

Bacton Wood Mill

River Ant / North Walsham & Dilham Canal |

|

|

February

1977

|

|

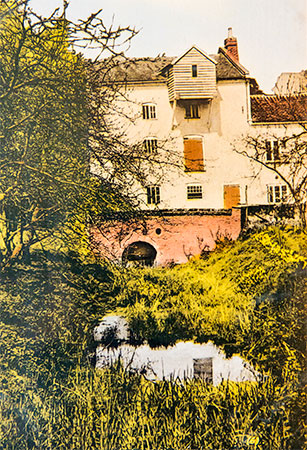

Bacton Wood watermill at Spa Common, North Walsham was on a Domesday site and the last working mill was rebuilt in 1747 and underwent further extensive modification c.1825 in anticipation of an increase in trade due to the opening of the North Walsham & Dilham Canal in 1826. Construction was of originally of white rendered brick with a slate roof, however unusually, the mill house had a Norfolk pantile roof, although, this too was changed to slate in later years. |

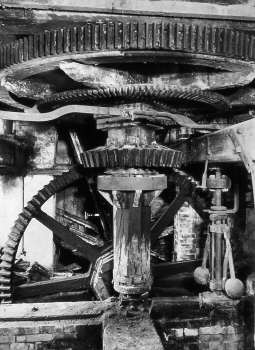

The new wheel was made of cast iron and was 18 feet in diameter and 8 feet wide and was almost certainly larger than the previous wheel, intending to take advantage of the increase in head of water. The pit wheel and wallower were both made of cast iron, as was the spur wheel, which meshed with the wooden teeth of the stone nuts. |

|

|

|

June

1967

|

June

1967 |

|

|

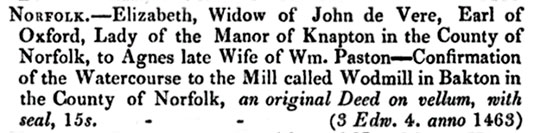

From a bookseller's catalogue - 1829 |

|

|

New

lucum 1971

|

|

The inventor, Sir William Cubitt was born at Dilham in 1775 where his father Joseph ran a mill. From an early age William helped his father in the windmill, showing particular aptitude in the repair of the machinery. A few years later in 1802 his father moved to Bacton Wood watermill and William joined him in 1804. William then had several jobs within Norfolk before moving back to Bacton Wood mill in 1807. On 9th May in that year was granted a patent titled 'Method of Equalising the Motion of the Sails of Windmills.' This was a system of self regulating shuttered windmill sails,known as Patent Sails that eventually became the industry standard, replacing the canvas covered Common Sails. It is said that he was associated with Ludham millwright, William England, who was some 15 years his senior, and it was he that installed the first of the patent sails in windmills at Horning and Stalham. William Cubitt then embarked on an illustrious career in civil engineering that included general, railway and waterway projects. He died in 1861. |

|

|

Sir

William Cubitt

|

|

Joseph Cubitt worked the water mill in conjunction with the nearby Bacton Wood postmill. |

|

Bacton Wood Mill |

All that Capital WATER MILL called Bacton Wood Mill,

(which is capable of manufacturing regularly about seven lasts of wheat

per week) with a small but comfortable dwelling house, good garden and

orchards, shrubbery, yards, stables, cow houses, piggeries, granary, cart-lodge,

and other convenient outhouses, and about nine acres of arable and meadow

land, situate in Edingthorpe and North Walsham in the county of Norfolk,

late in the occupation of Mr. Joseph Cubitt, deceased, and now in the

occupation of his Executors. The above Estate is wholly Freehold, and being situated upon the bank of a Canal navigable to Yarmouth, in a good corn country and populous neighbourhood, within a mile of the Marketplace of North Walsham, possesses facilities for carrying on a considerable London Trade at a comparative trifling expense. Possession of the Estate may be had at Midsummer or at Michaelmas next, at the option of the purchaser, who may be accommodated with one half of the purchase money on mortgage. For price and further particulars apply to Mr. Deyns of North Walsham, at whose Office a Map of the Estate may be seen. Norfolk Chronicle - 1829 |

William Harrison Wells was born on 24th September 1805, the son of William and Sarah Wells. William Wells snr, who was born c.1781 in Lound, Suffolk, married Sarah Harrison in Gt Yarmouth on 29th January 1804. William snr was almost certainly a miller by profession but it's not known where. He died at some time between the census in 1841 and 1851 and the 1851 census lists Sarah Wells as the widow of a miller. William jnr was given his mother's maiden name as a middle name and obviously learnt milling at an early age. He married Harriet Howes at West Somerton on 9th May 1832. |

|

|

|

1977

|

6th April 2003 |

|

|

|

1977

|

6th April 2003 |

|

On Monday (22nd) Edgar PAGE, aged 28, a miller in the

employ of Mr. William BURTON of North Walsham had been oiling some of

the works of the mill while it was at work and was found by Mr. Burton

(who had wondered at not seeing him since breakfast) lying on the second

floor of the mill quite dead with his head smashed and other injuries

from which death must have been instantaneous. It is supposed that his

clothes were caught by which he was drawn in by a horizontal wheel between

3 and 4 feet in diameter which appears to have taken him quite in and

to have flung him out on the floor. The deceased had been several times

cautioned not to run such risks as to oil the mill with a can when a pipe

was provided to avoid danger. He has left a widow and one child. On the

following day an inquest was held by W. H. SCOTT, Esq., Deputy Coroner

and a verdict of 'Accidental death' recorded. |

| Edgar Page was born in Ludham and was apprenticed at Hemsby towermill |

|

|

New

stone being installed c.1940

|

|

FATAL ACCIDENT |

|

c.1945 |

|

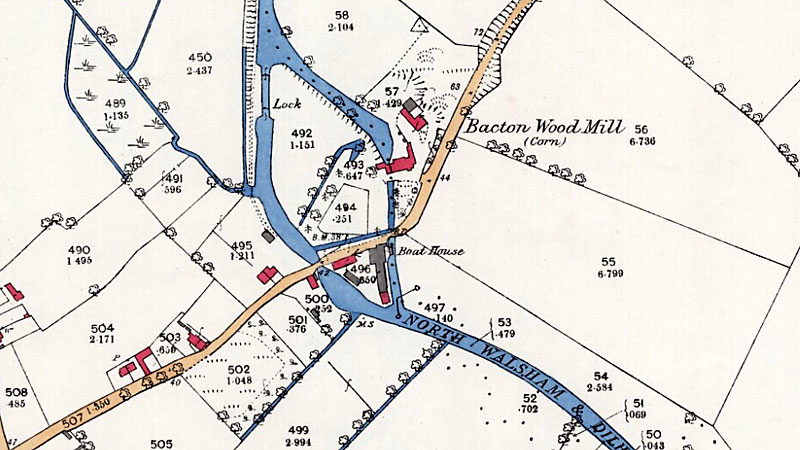

The North Walsham & Dilham Canal |

| This was the

only official canal in Norfolk and was really the canalisation of the River

Ant. It was made wider than most other canals in order to accommodate Norfolk

wherries. The main cargoes were offal to the two Antingham

Bone mills with return loads of fertiliser. Corn and flour moved in

and out of Bacton Wood and Swafield mills with

other commodities such as timber, farm produce and coal making up the majority

of the remainder of trade. It was hoped that coal would be the mainstay

cargo but this never materialised. The canal was just over 8¾ miles

long, ran from Smallburgh to Antingham and contained 6 locks: Honing, Briggate

mill, Ebridge mill, Bacton

Wood mill, Swafield lower and Swafield

Upper. 1812: Act of Parliament passed authorising construction of the canal July 1826: Canal opened having cost £32,000 to build 1885: Ailing canal sold for £600 but the company's London solicitor absconded with the money 1886: Scheme introduced to encourage tourist traffic c.1893: Antingham - Swafield section abandoned because of lack of traffic 1934: The wherry Ella, sailed from Bacton Wood Staithe for the last time 2003: Canal navigable for the first 2 miles as far as Honing Lock 2017: Section of canal near Royston Bridge rewatered |

|

On August 29th 1826, the canal was completed to the Antingham_Bone_Mills. It was officially opened when a large procession of boats carrying over 1000 people, led by The Lieutenant of The County and Lord Suffield, sailed the whole length. The day ended when some 55 local gentlemen retired for a dinner at the Kings Arms with the Lieutenant and Lord Suffield. |

|

|

|

Bacton

Wood lock c.1910

|

Bacton Wood lock in 1928 |

|

From 1874 to 1907 the the Press brothers worked wherries on the canal. One wherry was called Ella, she was about 55' long and 12' 6" wide with a draught of 3' 6." Her capacity was 20 tons and her incoming cargoes included grain for the mill, fishmeal, timber, coal, salt and even groceries and wine from Lowestoft or Yarmouth. Outgoing cargoes included flour, oak billets for fish smoking, and during autumn and winter, sugarbeet to Cantley factory. Ella was the last commercial craft to use the canal and left Bacton Wood Staithe for the last time in 1934. |

|

Bacton Wood Mill |

||||||||||||||||||||||||

Sale particulars for properties to be auctioned at the

Mart, Tokenhouse Yard, London, EC., on Wednesday 11th September 1907 at

two o'clock in then afternoon in eight Lots. The first seven Lots by instructions

of the Executors of the Will of Edward Press., Esq., deceased.

Auctioneer: Harry H. Arnold, 9 Bank Plain & Stand No. 72, Corn Hall, Norwich. Vendor's Solicitors: Messrs. Sadd & Bacon, Church Street, Theatre Street, Norwich. Lot 1: The North Walsham & Dilham Canal Lot 2: Dwelling House with garden (former toll house at Tonnage Bridge) Lot 3: Range of granaries at Bacton Wood Staithe Lot 4: The Red Brick and slated FREEHOLD WATER CORN MILL with Capital Residence and Premises Situate in the Parishes of Edingthorpe and North Walsham, Norfolk, facing the road from North Walsham to Bacton and adjoining the North Walsham & Dilham Canal and comprising: The most Substantially Built Red Brick and Slated WATER CORN MILL Erected in four floors, with Granaries and Store Chambers, having Brick Built Bridge with Brick Arches. The Red Brick Built with Corrugated Roof ENGINE HOUSE with Cement Floor and Boarded End; and adjoining is The Red Brick and tiled RESIDENCE containing on the Top Floor - Large Attic; On the first Floor - Landing, Four Capital Bedrooms and Box Room; On the Ground Floor - Entrance Hall, with cupboard under stairs, Sitting Room with register stove, Dairy wit brick floor; Kitchen with range and sink; Pantry; and a Room partitioned off and used as an Office with entrance from the Mill. Enclosed GARDEN in the Meadow in front and CAPITAL ENCLOSURE of OLD PASTURE LAND the whole containing an area of 2a. 1r. 18p. or thereabouts, as set forth in the following SCHEDULE.

The Purchaser of this Lot will have to pay the sum of £125. 4s. 0d. in addition to the purchase money for the Portable Engine and certain Mill Fixtures, and the Two Greenhouses erected in the Garden. The Owners and Occupiers of this Lot will have a right of entry (but on foot only) over 6-feet in width of the Property forming Lot 5, immediately adjoining the Mill House and Premises, for the purpose of carrying out repairs to the buildings sold as part of this Lot. Sale Particulars September 1907 |

|

SALE OF CANAL |

At the Mart, Tokenhouse yard, on Wednesday, Mr. Harry H. Arnold sold the North Walsham and Dilham Canal (running from Antingham basin to Wayford bridge) for £2,550, and Bacton Wood Mill for £550. The total amount of the sale was £4,305. Lynn Advertiser - 13th September 1907 |

|

|

|

1977

|

Tail

race 6th April 2003 |

|

A Dodman steam plant was in use during the later part of the 1800s to help with the summer water shortage. When the the cast iron boiler blew up, an 18 h.p. Hornsby hot bulb engine was installed c.1910. During restoration of the mill c.1984, this engine was eventually sold to enthusiasts and the intention was then to install the 40 h.p. Crossley engine from Aldborough Mill that standing in the cartshed. During the latter days of the war the mill was driven by a standby diesel engine as the canal had burst its banks and no water was available. The oat crusher was later removed by Barclay & Pallett to be fitted into Aylsham Mill. |

|

|

Main

gearing 1971

|

|

|

|

|

Pitwheel 1971

|

Pitwheel 6th April 2003 |

|

|

|

|

|

The tuns containing the mill stones in the 1970s

|

The tuns April 2003 |

|

The mill was last used by Barclay & Pallett & Co Ltd in 1944 and had started to become derelict before being sold to a sympathetic new owner on 25th May 1969 for £2,000. The new owner intended to leave the machinery intact and create a home around it. |

|

|

|

30th

June 2004

|

26th April 2009 |

|

|

|

27th September 2009 |

27th September 2009 |

|

|

|

Bacton Wood lock 7th March 2011 |

7th March 2011 |

|

Organ pipes at an old water mill |

"You may not think it, but organ pipes are very personal things. They are the soul of the organ." I had never thought about it at all until Mr. Derek Jones told me this while he was casting long sheets of pipe metal at his workshop at Bacton Wood Mill, Spa Common, North Walsham. A Surrey man, he came to Norfolk some ten years ago and learned his unusual craft of organ pipe making at Trunch. Later he was in parnership with Mr. Clifford Hyatt, now of Miller Organs in London. On a good day Mr. Jones can cast up to 20 sheets, using a stout mahogany box - made from part of the old booking office at Thorpe Station - with no bottom. After pouring in the molten metal at 425 degrees Fahrenheit, he pushes the box down a long table covered with glazed linen, leaving behind a mottled silvery sheet. From this stock he cuts pieces to be rolled and soldered into tubes, some thinner than a pencil ranging to others up to four feet long and 4½ inches wide. He likes working with the small ones and although not a musician, he knows all the theory of organ building. When an order is completed, he delivers the pipes personally, usually in the London area, but seldom sees his work assembled. As a contrast to making these delicate pipes, Mr. Jones and his wife Joyce, who hails from Hoveton, have a heavier task constantly on hand in converting the old water mill into a home. Much of the roof, stairs, windows and flooringhas been renewed by Mr. Jones, who shapes wood as expertly as he does metal. At ground level is the massive cogged wheel built around the shaft that turned the millstones, still intact in their wooden covers. Mr. Jones believes there are only two other water mills still complete in this part of the county, at Burgh and Hanworth. All he needs is the water, for here the North Walsham and Dilham Canal is nothing but an unsightly overgrown ditch. Even without the water, though, Bacton Wood Mill could be made to grind again if only its owner could replace the 5-foot flywheel from the Ruston auxiliary engine that was removed from Glandford years ago and lateer shipped to the Continent. Eastern Daily Press - Thursday 20th January 1972 |

| OLD MILL WITHOUT WATER Canal key to restoration |

A NORTH WALSHAM man is seeking the support of a Government department and five other authorities in a bid to get a 226-year-old Norfolk watermill working again on a limited basis. Mr. Derek Jones bought Bacton Wood Mill - a grist mill - at Spa Common, North Walsham, nearly four years ago. It was semi-derelict. He and his wife have renewed the roof, repaired most of the brickwork and made themselves a flat on the top floor. Now he feels he has a little time to think about restoring the waterwheel - about 30 of its paddles are missing - and the grinding stones. In granting permission for the change of use of the mill to a house, planners made it a condition that the wheel and three pairs of grinding stones should be kept in the building. Eastern Daily Press - 11th May 1973 |

His dream |

Mr. Jones's dream is to see the wheel and one pair of stones turning again. For this to come true a flow of water would have to be restored in the upper reaches of the disused North Walsham and Dilham Canal over a distance of about a mile from Swafield Lock to Bacton Wood Mill Lock. As there is still a small flow of surface water in the canal he feels that increasing it to a depth of about 18 inches would not cause any problems. It would be necessary to clean out the canal bed. A weir would have to be constructed across the top of the lock at Bacton Wood Mill and some form of aqueduct would have to be made across a breach made in the canal bed some years ago. this could incorporate a control weir to apportion the water between the canal and a drainage ditch which passes North Walsham U.D.C.'s sewage farm. It would also be necessary to repair a breach in the canal bank above Royston Bridge through which water at present escapes into the drainage ditch. Mr. Jones has put his ideas to the Department of the Environment, the East Suffolk and Norfolk River Authority, Smallburgh Internal Drainage Board, Norfolk County Council, North Walsham U.D.C. and Smallburgh R.D.C. He had previously been in touch with the Canal Company. Though it would be opposed to building up a head of water such as the canal used to carry it had no objection to a small flow such as Mr. Jones has suggested to operate the wheel and a pair of stones. Mr. Jones said he hoped that perhaps the River Authority might lend a hand with some of the work and that the County Council might make a grant towards the cost in the same way that it had given financial assistance for the restoration of some windmills. If no help was forthcoming from the authorities, but they did not object to his plan, then he would try to ge the work done voluntarily. Mr. Jones made it clear there was no question of trying to bring the mill back into commercial use. Bacton Wood Mill occupies a site dating back to Domesday and was rebuilt in 1747, Mr. Jones said it was last used by Barclay, Pallett & Co. Ltd. in 1944. Eastern Daily Press - 11th May 1973 |

|

One man's mission to restore Bacton Wood Mill and his stretch of the North Walsham and Dilham Canal |

As a practical man who does not mind getting his hands dirty, it was inevitable that when Laurie Ashton bought a disused north Norfolk mill in 1994 he would eventually want to restore it. And because Bacton Wood Mill is beside Norfolk's only canal - long disused - Mr Ashton is also very keen to bring that back into use as well. He is so passionate about the project that in 2009 he and his wife Julie formed the Old Canal Company and bought a two-and-a-half mile stretch of the North_Walsham_and_Dilham_Canal, between Ebridge Mill lock and Swafield Bridge. Mr Ashton, 65, knows what he is talking about when it comes to both machinery and water. A chartered electrical engineer from Essex, he was a regular weekend visitor to the area in the 1960s as one of the first volunteers on the North Norfolk Railway. When the couple moved to north Norfolk, they bought two boatyards, at Wayford and Hoveton. The near nine-mile canalisation of the River Ant opened in 1826 and stretched from Antingham to Wayford bridge. It included six locks capable of taking small wherries which carried goods including flour and animal feed. The last wherry to use the canal was the Ella in 1934 after which the waterway gradually became choked with vegetation and the section above Bacton Wood Mill dried out. Mr Ashton hopes to remedy that. Sparing with words but generous with his time and expertise, he explained: "I think it will look a lot better restored than it does full of reeds and other stuff." The mill machinery had been intact but "worn into the ground" he said. The 18ft 6in wheel was in situ, but rusted and missing its wooden paddles. Over the years he has rebuilt the tail race bridge, stabilised all the brickwork in the wheel pit and restored the wheel, though it still lacks the paddles. But the centre piece of Mr Ashton's restoration work to date is the lock, once completely overgrown and suffering from neglect. With the help of retired brickmaker John Brice he has spent three years restoring it, investing about £40,000 alone in some 57,000 bricks, and about £2,500 on the bottom gates. The top gates are next on the list. This winter Mr Ashton hopes to kickstart the re-watering of the canal above his mill by filling a breach in the bank near Royston Bridge and installing a sluice gate he has made. Success would mean the wheel of a mill first recorded in the Domesday Book could turn once again. Alex Hurrell, Norwich Evening News - Thursday 14th November 2013 |

The river divided above the mill and the section that used to feed the mill has long since dried up as the level of the river and the canal dropped to nearer natural levels once the canal closed. |

|

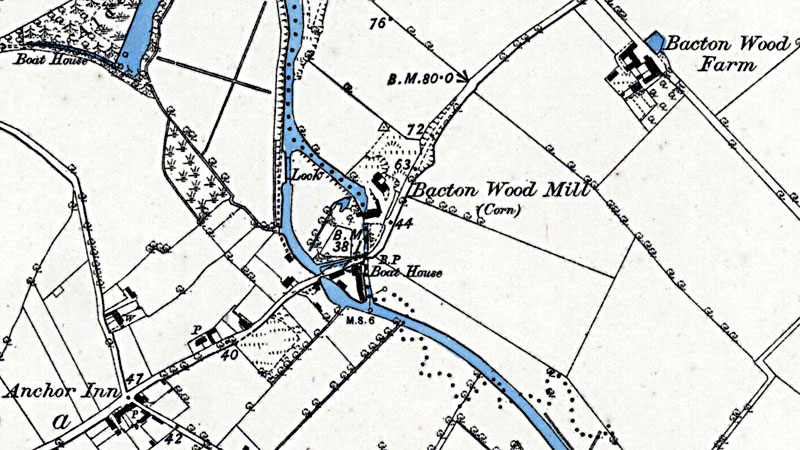

O. S. Map 1884 |

|

O. S. Map 1885 |

|

O.S. Map 2005 Image reproduced under licence from Ordnance Survey |

| 1463: Document detailing confirmation of the mill watercourse c.1525: Mill belonged to Sir William Paston c.1747: Mill rebuilt 1802 - 1822: Joseph Cubitt miller, also worked Bacton Wood postmill c.1825: Mill underwent extensive rebuild and refurbishment in time for canal opening Bryant's map 1826: Wood Mill Enclosures Award & Map 1828: Devisees of Joseph Cubitt - watermill & post mill Pigot's 1830: George Cubitt, miller, WOOD MILL White's 1836: William Harrison Wells; also Dilham Pigot's 1839: William Harrison Wells, Wood mill White's 1845: William Harrison Wells; also Dilham

White's 1864: William Burton, corn miller; (h Bacton wood mill) Monday 22nd September 1862: Edgar Page (28) died in the mill machinery 5th March 1867: William Burton died 1874: Edward Press opened a boatyard at Ebridge and used it as a base for his 5 wherries (incl passengers)

Kelly's 1883: Press Bros. 16th March 1886: Edward Press purchased the canal for £600 White's 1890: Press Brothers, millers, corn & coal merchants, Spa Common; and Yarmouth - also Smallburgh Kelly's 1892: Press Bros., millers

2nd July 1906: Edward Press died 11th September 1907: Edward Press' property sold at auction including the mill and NW & Dilham Canal Kelly's 1908: Sidney Stackwood, miller (water), Bacton Wood mill, Spa common c.1910: 18 h.p. Hornsby hot bulb engine installed after the original cast iron steam boiler blew up Kelly's 1912: Pallett, Barclay & Co. Kelly's 1922: Barclay, Pallett & Co Ltd Kelly's 1937: Barclay, Pallett & Co Ltd 1944: Mill finally ceased operation under Barclay & Pallett. Last miller was Will Grimes 25th May 1969: Mill sold for £2,000 to Derek Jones 1972: Derek Jones manufacturing organ pipes in the mill 1973: Derek Jones, owner, hoping to put mill back into working order 11th May 1987: Mill designated with a Grade ll listing 1994: Mill bought by Laurie Ashton 2013: Mill restoration nearing completion |

If you have any memories, anecdotes or photos please let us know and we may be able to use them to update the site. By all means telephone 07836 675369 or

|

| Nat Grid Ref TG 29993067 | Copyright © Jonathan Neville 2018 |